A solenoid valve is an electromechanically actuated valve that runs on 12 volts. Different solenoid valves have different properties for the fluid they control, the electric current they utilize, the magnetic field they produce, the mechanism they use to control fluid flow, and more. Read More…

Solenoid Solutions manufacturers custom direct-acting 2 and 3-way solenoid valves and multi-valve manifolds for OEMs in the medical, appliance, transportation, power generation and industrial equipment markets.

Our solenoid valves are all tested in house following very strict quality guidelines. We opened our doors in 1936 and ever since then we have been committed to bringing top of the line products and customer service that cannot be beat!

At Plast-O-Matic Valves, we are dedicated to designing and manufacturing high-performance fluid control solutions, with solenoid valves as a core part of our expertise. We take pride in engineering these valves with precision and reliability, ensuring they deliver consistent performance in demanding applications across a wide range of industries.

At Brandstrom Instruments, we are dedicated to delivering reliable and innovative solutions in fluid control, specializing in the design and manufacturing of high-quality solenoid valves. With decades of experience in engineering precision components, we take pride in offering products that meet the strict demands of industries requiring accurate flow regulation, durability, and efficiency.

We are proud to be DEMA® Engineering Company, a trusted name in fluid control and dispensing solutions. With decades of expertise, we design and manufacture high-quality solenoid valves that deliver reliable performance in a wide range of industrial and commercial applications.

At Aquatrol, we take pride in being a trusted manufacturer of high-quality solenoid valves designed for dependable performance across a wide range of industries. With decades of hands-on expertise, we have built a reputation for precision engineering, innovative solutions, and a commitment to excellence that ensures every product we deliver meets the highest standards.

More 12 Volt Solenoid Valve Manufacturers

For applications where low voltage and safety is of the utmost importance, such as water fountains, vending machines, and coffee makers, an ideal solution is small 12-volt solenoid valves and small compact, low-power valve coils that draw under 500 milliamp, 12 volt brass, stainless steel, and plastic solenoid valves (12vdc DC direct current or 12vAC alternating current).

They have lower power consumption and energy-saving qualities, but they also have the additional advantage of lower heat, which extends working life. Working with hard water applications calls for extra care because calcium (limescale) buildup is reduced by low heat. Most of the time, wall-mounted transformers or 12-volt battery packs can power low-power 12-volt solenoid valves.

Types of 12 Volts Solenoid Valves

Direct Acting Solenoid Valve

These valve types operate with the most basic mechanism. A plunger in a direct-acting solenoid valve, for instance, shuts a small aperture without the aid of an external force. As a result, these solenoid valves have a quick response time. They can also function under various pressures, ranging from the lowest to the highest permitted values. An orifice in a direct-acting solenoid valve that is NO (normally open) or NC (normally closed) closes when an electric current is applied.

The orifice in an NC direct-acting valve is closed and only opens when the solenoid coil windings are energized. The three-way two-position solenoid valve is a different type of direct-acting valve. The only difference between it and the 2/2 valve is how fluid is exhausted. It can do this by utilizing a seal at the top or bottom of the plunger. There are benefits and drawbacks to using direct-acting solenoid valves.

First off, these valves are precise and quick to react. These valve types also benefit from operating with a range of line pressures, from low to high. The main drawbacks of direct-acting solenoid valves are their size and strength. Additionally, because the valves depending on the solenoid coil's closing force, they frequently require large currents. If the systems are large-scale, this frequently entails huge solenoid construction.

Pilot-Operated Solenoid Valve

A pilot solenoid valve, also known as an indirect-operated valve, uses the pressure differential between the valve ports to close or open the outlet. These valves include a few extra pieces and are more complicated than direct-acting valves.

Working Principle of a 12 Volt Solenoid Valve

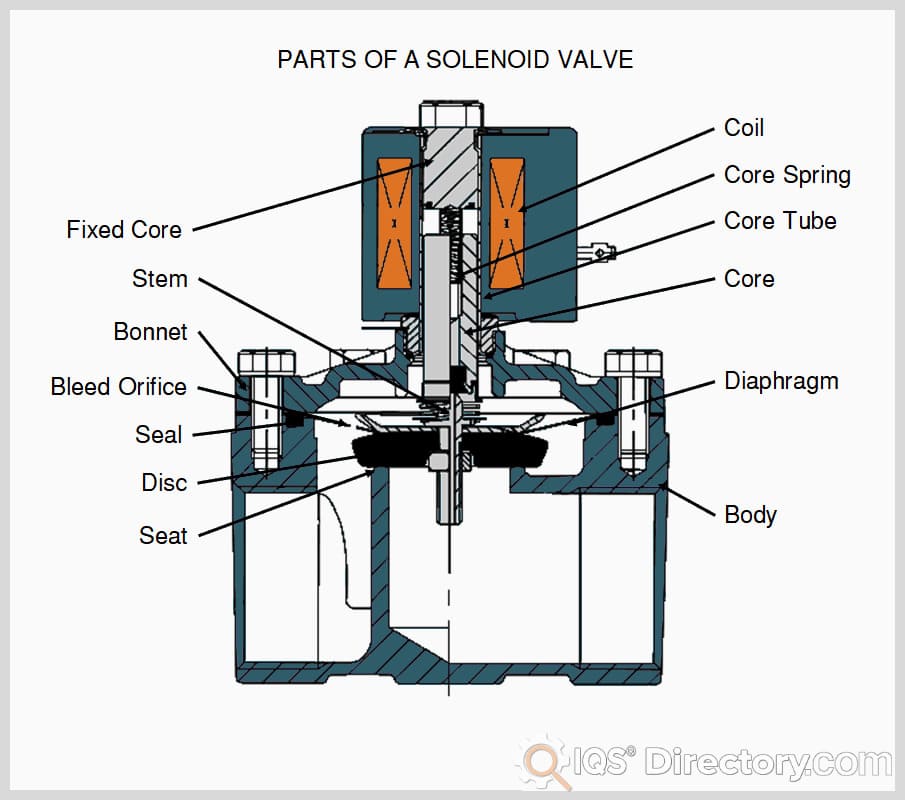

A diaphragm separates the intake and outlet ports of these solenoid valves. The medium can move into the upper chamber through a tiny hole in the diaphragm. This chamber is linked to the low-pressure port via a short conduit. The valve is kept closed by the pressure in the system and a little spring. The pilot orifice opens when the solenoid is activated, lowering the pressure in the upper chamber.

The diaphragm lifts, as a result, allowing the medium to flow from the intake to the outlet port easily. The pressure chamber amplifies a pilot-operated solenoid valve's closing and opening forces. This makes it possible for tiny solenoids to control a high-flow line.

This solenoid valve typically doesn't require huge amounts of current because of the amplified pressures. However, pilot solenoid valves have a few restrictions despite their powerful action. First, they may control a medium that only moves in one direction because they are a one-way solenoid valve.

In addition to being slower than direct-acting solenoid valves, pilot solenoid valves require a minimum operating pressure level and cannot be used with 0-bar circuits. Pilot solenoid valves are appropriate for systems with sufficient pressure differential, such as irrigation systems and car wash equipment. The majority of their applications involve large flow rates or capacities. These consist of devices that regulate water flow, such as faucets.

Two Way 12 Volt Solenoid Valves

These valve types shut off or open the fluid flow using two ports. A two-way solenoid valve, for instance, is categorized as generally open if the orifice permits media to flow. At the same time, the coil is de-energized and normally closed when energizing the coil permits fluid to flow via either port. Solenoid valves that are generally closed, or NC, are more prevalent than those that are normally open. Systems with two-way solenoids that require media release and restriction. These consist of gear-like air compression devices.

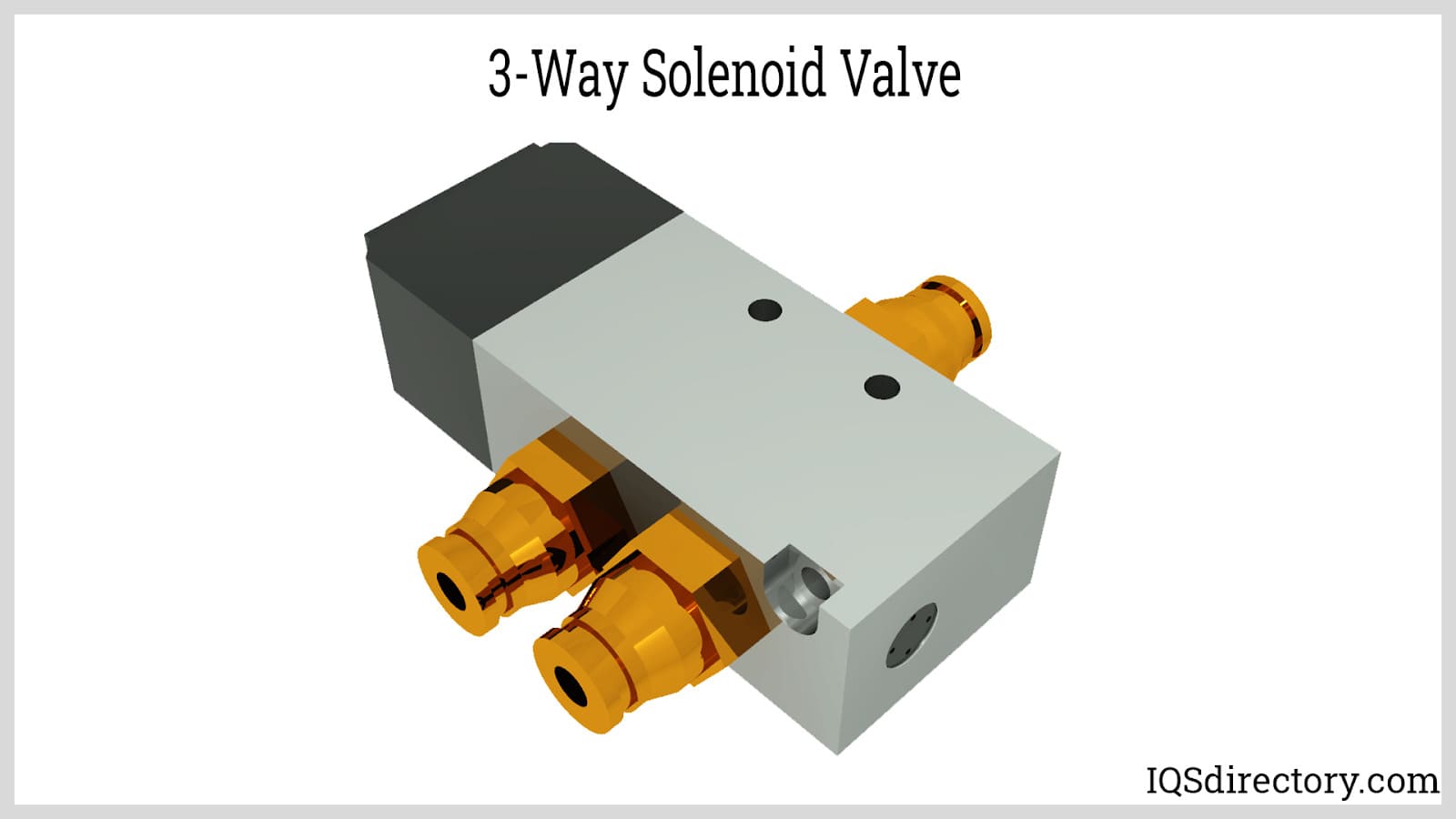

Three-Way 12 Volt Solenoid Valve

Typically, a 3-way solenoid valve has three ports and two distinct orifices. Depending on the condition of the solenoid coil, the two orifices open in turn. These valve types typically have two inlet ports and one exit. Consequently, a three-way solenoid valve mainly combines two separate fluids when utilized in this form. Some three-way solenoid valves use a single inlet port and two exits. By routing a medium through the other outlet port, this type of design enables the valve to regulate the flow of a medium in one of the output ports. For instance, 3-way solenoid valves are used in domestic items like the dishwasher.

Four-Way 12 Volt Solenoid Valve

Four ports are used by this kind of valve: two pressure inlets and two exhaust outputs. To operate double-acting solenoid valve actuators, 4-way valves are frequently employed. This is because the actuator or cylinder receives incoming pressures through the input ports, and the exit pipes are large pressure holes.

Choosing the Proper 12 Volt Solenoid Valve Manufacturer

To make sure you have the most productive outcome when purchasing 12 volt solenoid valves from a 12-volt solenoid valve manufacturer, it is important to compare at least 4 manufacturers using our list of 12 volt solenoid valve companies. Each 12-volt solenoid valve manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each 12 volt solenoid valve company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple 12-volt solenoid valve businesses with the same quote.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services