This device, sometimes called a “5 port valve,” can be powered by air or electricity, with air pressure being the most common source of power. Four-way solenoid valves have five ports to allow air pressure to move an actuator or rod back and forth inside the valve, in order to control the direction of flow. Read More…

Solenoid Solutions manufacturers custom direct-acting 2 and 3-way solenoid valves and multi-valve manifolds for OEMs in the medical, appliance, transportation, power generation and industrial equipment markets.

Our solenoid valves are all tested in house following very strict quality guidelines. We opened our doors in 1936 and ever since then we have been committed to bringing top of the line products and customer service that cannot be beat!

At Plast-O-Matic Valves, we are dedicated to designing and manufacturing high-performance fluid control solutions, with solenoid valves as a core part of our expertise. We take pride in engineering these valves with precision and reliability, ensuring they deliver consistent performance in demanding applications across a wide range of industries.

At Brandstrom Instruments, we are dedicated to delivering reliable and innovative solutions in fluid control, specializing in the design and manufacturing of high-quality solenoid valves. With decades of experience in engineering precision components, we take pride in offering products that meet the strict demands of industries requiring accurate flow regulation, durability, and efficiency.

We are proud to be DEMA® Engineering Company, a trusted name in fluid control and dispensing solutions. With decades of expertise, we design and manufacture high-quality solenoid valves that deliver reliable performance in a wide range of industrial and commercial applications.

At Aquatrol, we take pride in being a trusted manufacturer of high-quality solenoid valves designed for dependable performance across a wide range of industries. With decades of hands-on expertise, we have built a reputation for precision engineering, innovative solutions, and a commitment to excellence that ensures every product we deliver meets the highest standards.

More 4 Way Solenoid Valve Manufacturers

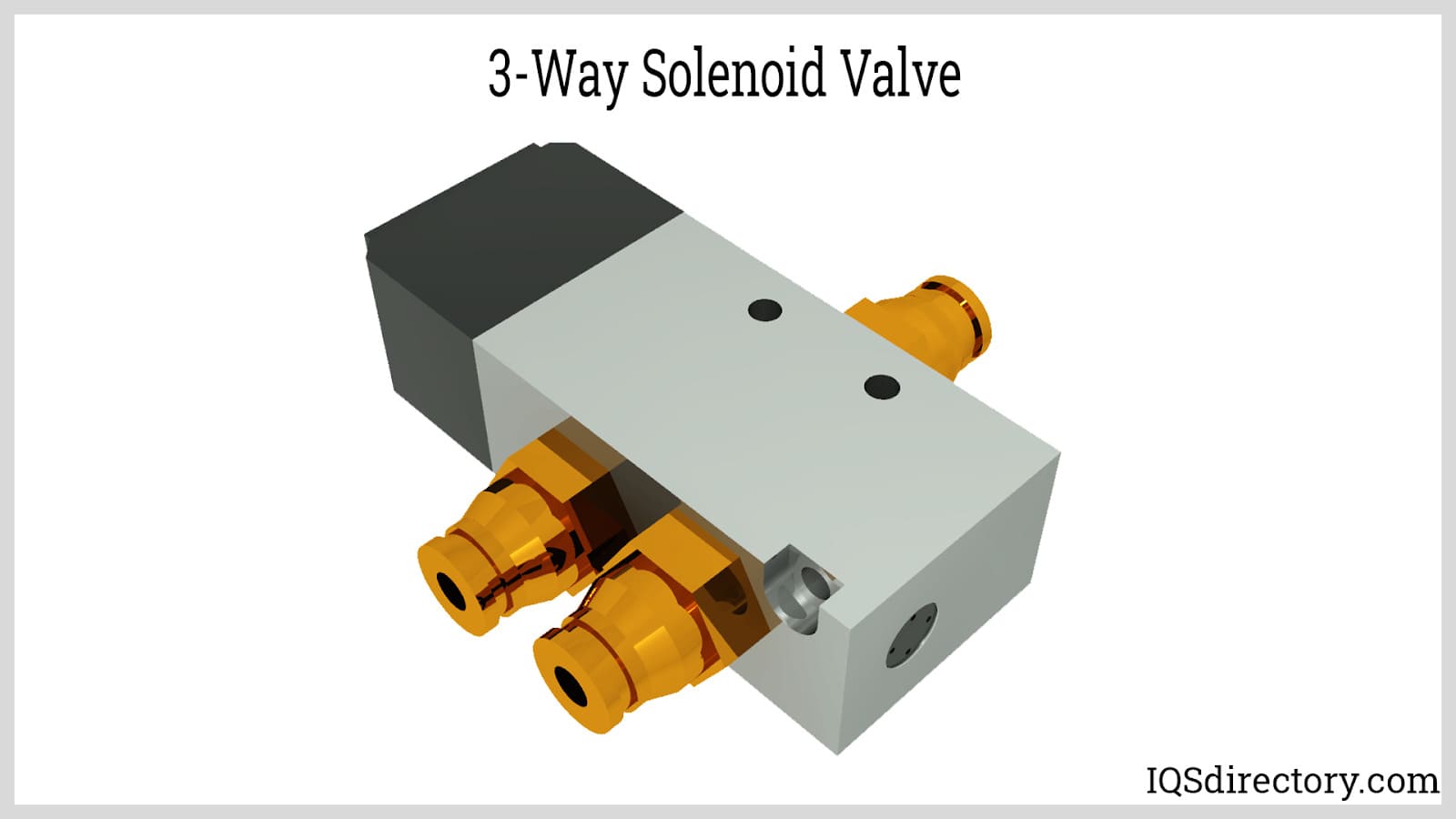

There are a few different common configurations of 4 way solenoid valves.

One design contains one liquid inlet and two outlets. In this case, the direction of flow is controlled by the position of the internal actuator. The other two ports, one on each end, aid in air pressure connections. As air pressure enters one end, the rod moves and internal channels allow the fluid to flow in one direction. If air pressure enters at the other end, the rod moves in the opposite direction, revealing a different flow channel that allows fluid to go in the other direction.

These 4 way solenoid valves are useful because they permit one device to control flow in multiple directions. Since one valve can be used for more than one control task, they are an advantageous purchase for a consumer whose control system only has a few connections available.

Another type of 4 way solenoid valve is a stepper valve, which employs a ratchet system to advance the valve each time it is energized. Gears inside the valve move the actuator each time an electrical signal or burst of pressurized air is sent. Stepper valves can be used to turn flow on and off in a predetermined sequence or to activate different systems connected to the valve.

The stepper variety of 4 way solenoid valves are best suited to tasks that occur in order, or sequential positioning, without the need to go back to its original position or jump to a new one. This is because each signal on the stepper valve turns it to a new position, without the ability to return to a previous position until the signal is lost or the operation is complete. Uses well-suited to the stepper valve are, among others, lawn sprinkling, water softener regeneration, and pool chemical treatment.

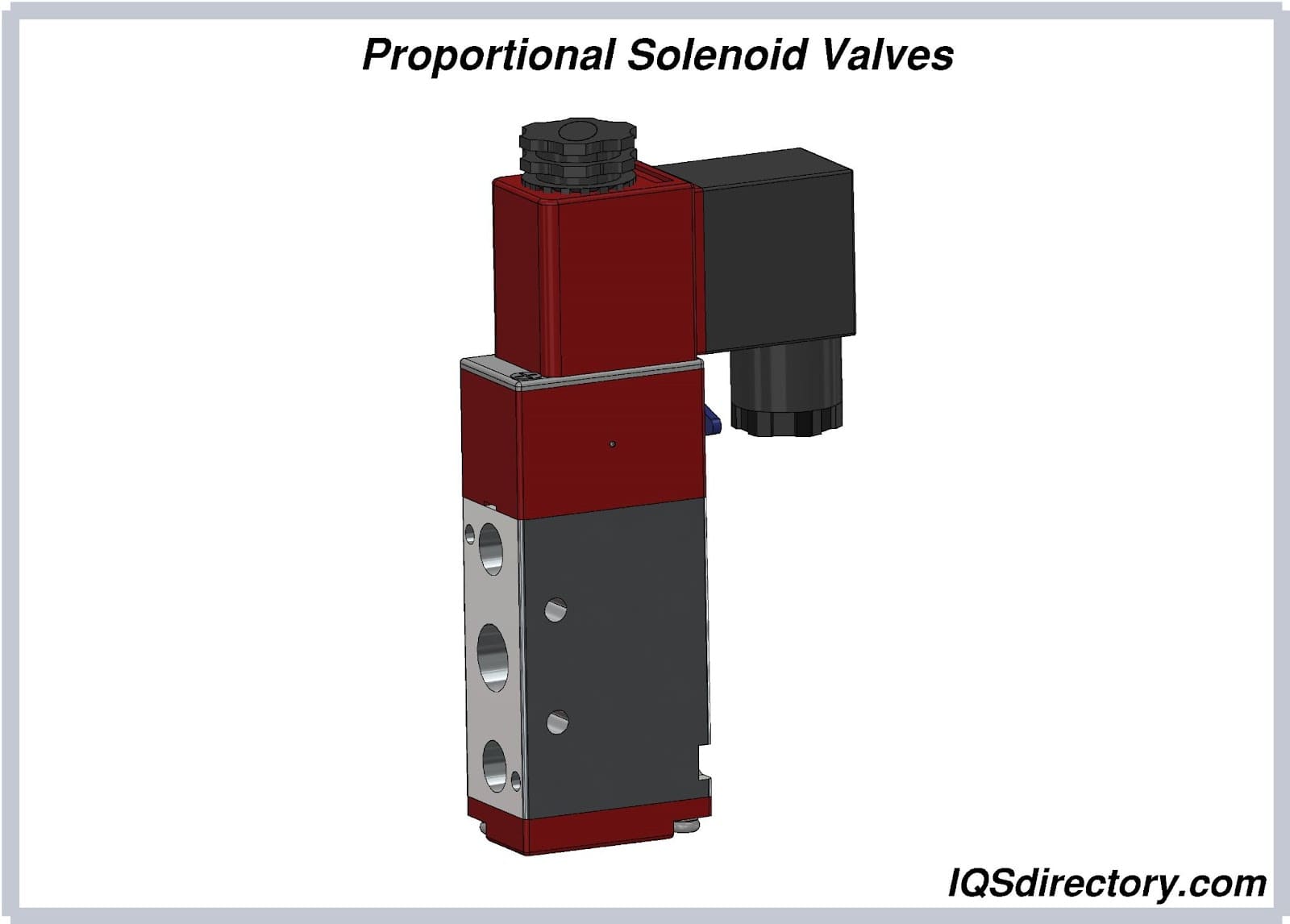

Since the development of greater computer technology, some solenoid valves have become equipped with "intelligence," able to use sensor readings. For example, as signals are sent from various points in a chemical process, a solenoid can make decisions on how to operate. Valves with this type of programming are able to make operating choices without being connected to a central control circuit.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services