More Solenoid Valve Manufacturers

Solenoids and solenoid valves are highly favored across a wide range of industries due to their safe and swift switching capabilities, exceptional reliability, long operational life, and compact, space-saving design. These electromechanical devices are critical for automating fluid and gas control processes. While solenoid valves find widespread use in numerous sectors, they are especially prevalent in residential, appliance, industrial, and commercial applications, including factory automation, process control, and energy management systems.

Common uses of solenoids and solenoid valve assemblies include refrigeration, HVAC and air conditioning systems, power washing equipment, agricultural air conditioning, pneumatic and hydraulic systems (such as motors, actuators, cylinders, and buffers), compressed air systems, automotive engineering (fuel injection, emission control, transmission systems), water treatment, irrigation control, fire suppression, and a variety of household appliances. Their ability to precisely control the flow of liquids and gases makes them indispensable for both industrial process automation and everyday consumer products.

Are you searching for the right solenoid valve for your application? Learn how to select, size, and specify a solenoid valve by exploring common use cases, industry standards, and technical considerations below.

The History of Solenoid Valves

The evolution of the solenoid valve began in 1910, when ASCO Numatics manufactured the first solenoid control valve. This innovation helped automate the control of liquid and gas flow, revolutionizing process industries. By the 1950s, solenoid valve manufacturers had transitioned to plastic-molded solenoid valves, which enhanced efficiency, reliability, and resistance to corrosion and chemicals—critical for sectors like chemical processing, water treatment, and food manufacturing.

The trend of advancements persisted into the late 20th century. In the 1970s, automatic shut-off solenoid valves emerged, offering safer and more user-friendly alternatives to manual shut-off valves. These advancements improved safety and efficiency in critical infrastructure such as gas pipelines and industrial plants.

Global governments and independent organizations established solenoid valve standardizations in the 1990s. These standards facilitated international trade, simplified company collaborations, and made maintenance easier. Today, updated standards also limit the use of hazardous substances in valve production, enhancing their environmental friendliness. Modern innovations in valve fabrication and usage now prioritize health and sustainability, with many manufacturers focusing on energy-efficient, low-leakage, and RoHS-compliant designs.

Curious about solenoid valve technology trends? Explore how modern solenoid valve innovations can benefit your operations.

Design

Production Process

Manufacturers craft solenoid valves using a variety of precision engineering techniques, including CNC machining, laser welding, injection molding, coil winding, and automated assembly. After fabricating the individual parts, such as the electromagnetic coil, valve body, plunger, spring, and seals, the components are meticulously assembled and quality tested. Automated production lines and advanced metrology ensure high performance and reliability, even in demanding environments.

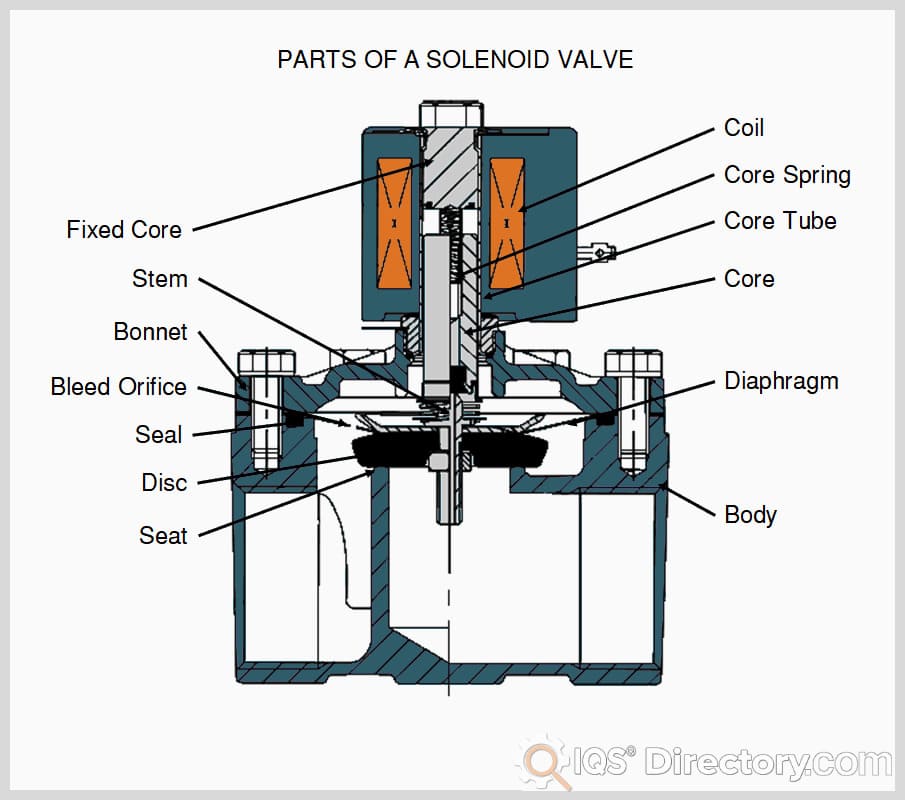

The essential components of a solenoid valve include the solenoid coil (electromagnetic actuator), the valve body, an inlet port, an outlet port, a spring, an orifice, and an actuator or plunger. High-quality seals—often made from elastomers, PTFE, or metal—ensure leak-free operation and long service life, even under high pressure or corrosive conditions.

Materials

Manufacturers have a wide array of materials at their disposal to construct solenoid valves, showcasing the product’s adaptability for various operating environments. Common valve body materials include plastics such as PVC (polyvinyl chloride), natural polypropylene, PTFE (polytetrafluoroethylene/Teflon), and CPVC (chlorinated polyvinyl chloride), as well as metals like stainless steel, bronze, aluminum, and brass. The choice of material directly impacts the valve’s chemical resistance, durability, and suitability for specific fluids or gases. Seals are typically crafted from rubber compounds like Viton, NBR (nitrile butadiene rubber), EPDM, or even stainless steel for high-temperature or aggressive media applications.

Looking for corrosion-resistant or food-grade solenoid valves? Discover which materials are best for your industry and application.

Design and Customization

The design of a solenoid valve is dictated by specific application requirements, which include the nature of the fluid or gas (its corrosiveness, hazardousness, viscosity, acidity, particulate content, and temperature), the operational environment (indoor/outdoor, hazardous area, sanitary conditions), usage frequency (continuous or intermittent operation), and compliance with relevant safety or industry standards. Based on these criteria, manufacturers select key design elements such as valve size, pressure rating, material, valve type (direct-acting, pilot-operated, proportional), connection configuration, flow rate capacity (Cv value), voltage, and the number of ports or positions.

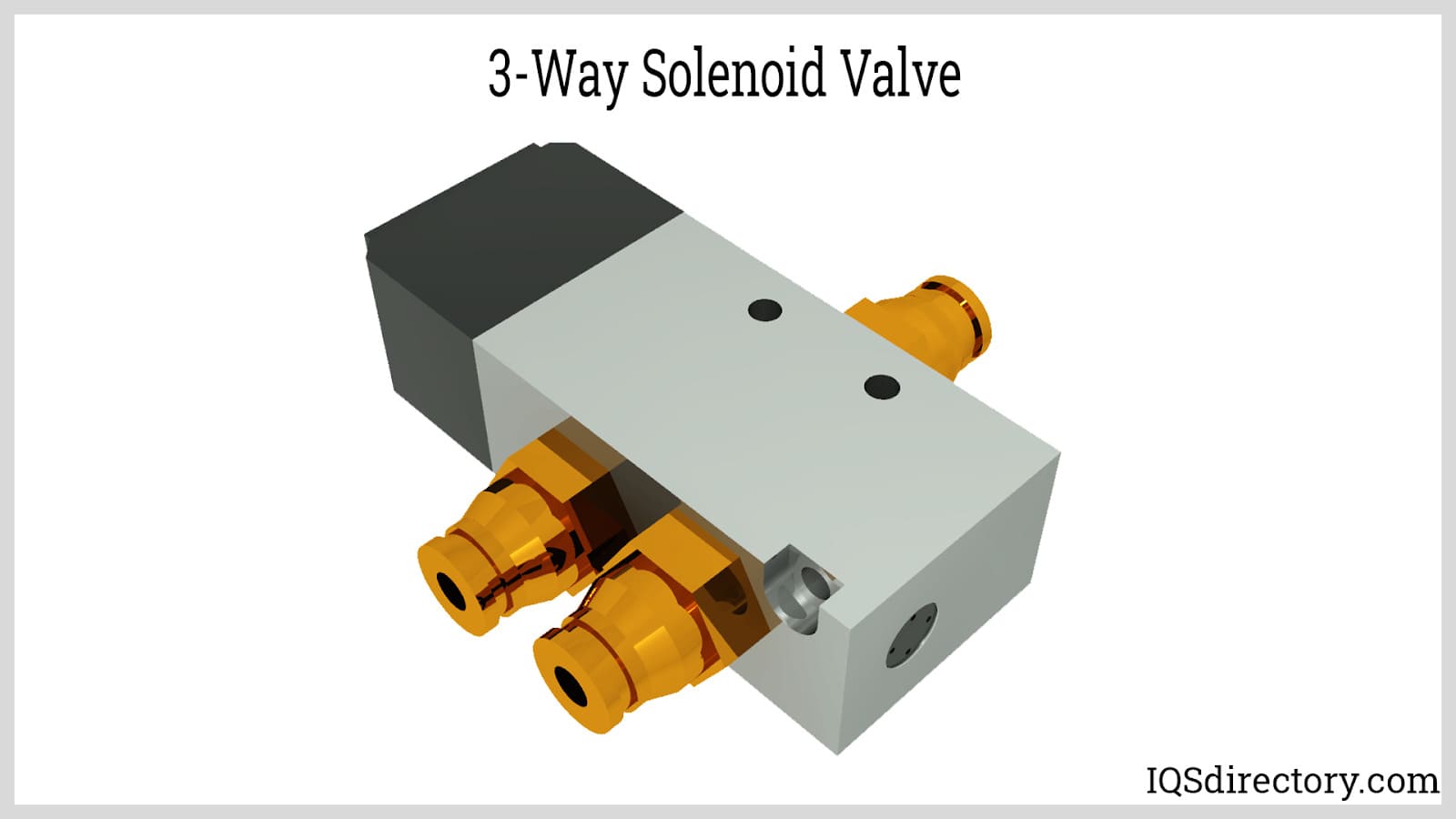

Suppliers offer extensive customization options to tailor the solenoid valve system to your specific needs, empowering users to make the best choices for their unique applications. Standard valves typically have two connection areas and one orifice, but custom designs can feature three or more ports, multiple orifices, and specialized actuation methods. While most solenoid valves operate on standard 12-volt DC or 24-volt AC/DC power sources, custom options can include 3-volt, 6-volt, 48-volt, or even high-voltage configurations. Additional features like pressure regulation, manual override, low-power coils, explosion-proof enclosures, and rapid response times can be specified for demanding or specialized use cases.

Not sure which solenoid valve design fits your requirements? Contact a solenoid valve expert or request a quote for custom solutions.

Features

Solenoid valves operate through two primary components: a solenoid coil and a valve mechanism. The coil is a magnetized wire wound into a helical shape, which, when energized by an electric current, generates a magnetic field. This field transforms electrical energy into mechanical energy, moving the actuator or plunger. The actuator, an extension of the valve with an attached spring, shifts the valve between open and closed positions, precisely controlling the flow of liquids or gases.

Solenoid valves come in two types: normally closed (NC) and normally open (NO). In NC valves, a plunger held by the solenoid coil blocks the current flow. To allow flow, an electromagnetic charge is sent through the coil, lifting the plunger. Conversely, NO valves remain open until the solenoid is activated, which then closes the valve. Some advanced models offer latching or bi-stable operation for energy-saving control.

Key features to consider when evaluating solenoid valves include response time, power consumption, duty cycle, leak-tightness, compatibility with media, environmental protection (IP/NEMA ratings), and ease of maintenance. These attributes impact performance in automated process control, safety shutdown systems, and precision dosing or metering applications.

Want to compare solenoid valve features side-by-side? Read our solenoid valve selection guide for in-depth feature comparisons.

Types

Solenoid valves are categorized by three general components to aid manufacturers and engineers in selecting the optimal valve for any process automation or fluid control application:

- Material Being Controlled: Examples include solenoid water valves, solenoid air valves, oil solenoid valves, chemical solenoid valves, and steam solenoid valves. The compatibility of the valve with the medium ensures safe and efficient operation.

- Valve Construction/Design: Types include proportional solenoid valves, 2-way, 3-way, 4-way, and 5-way solenoid valves, plastic solenoid valves, miniature/micro solenoid valves, high-pressure valves, and specialty valves (e.g., pinch, diaphragm, or angle seat valves).

- Power Source: Examples include 12-volt solenoid valves, 24-volt solenoid valves, pneumatic solenoid valves, and AC/DC driven valves. The available power source determines the appropriate coil and safety measures.

Solenoid Water Valve

Also known as hydraulic solenoid valves, these valves direct water flow using pilot-operated, normally open, or normally closed mechanisms. They are commonly used in irrigation systems, water filtration, beverage dispensing, and reverse osmosis equipment. Their rapid response and leak-tight shutoff are vital for water conservation and system protection.

Solenoid Air Valve

Also called gas solenoid valves, air valves, or pneumatic solenoid valves, they regulate air and gas flow with diaphragms and controlled air pressure. These valves are widely used in industrial automation, pneumatic tools, HVAC controls, and combustion systems. They can handle both standard pressures, such as those for home heating and cooling, and extremely high pressures, as required for industrial pneumatic machinery and process automation.

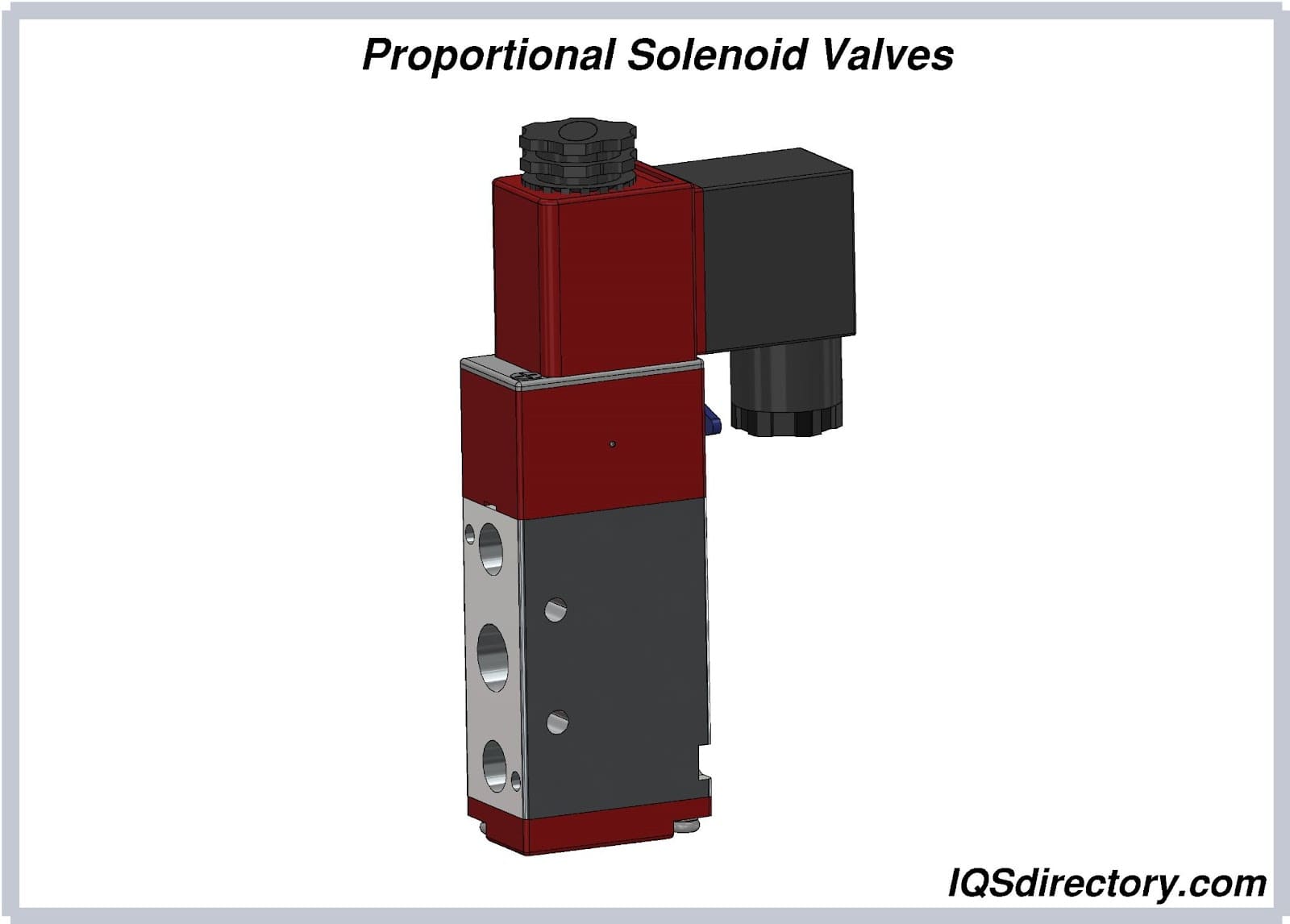

Proportional Solenoid Valve

These valves offer advanced flow control capabilities, enabling variable flow that is directly proportional to the electrical control signal. Proportional solenoid valves are essential in process industries requiring precise dosing of chemicals, gases, or liquids, as well as in analytical instrumentation, medical devices, and laboratory automation.

Twelve-Volt Solenoid Valve

Twelve-volt solenoid valves operate on a 12V DC power source and are standard for automotive, marine, solar, and portable equipment applications, thanks to their compatibility with battery-powered systems and low energy consumption. They are available in a variety of sizes, flow capacities, and material options to meet diverse market needs.

Solenoid valves are either pilot-operated, direct-acting, or semi-direct operated.

Pilot-Operated Solenoid Valve

Pilot-operated solenoid valves combine a main hydraulic or pneumatic valve with a smaller solenoid valve, using a diaphragm to create differential pressure and control flow. These valves are ideal for large flow rates and higher pressures with minimal power consumption. They are commonly used in water treatment plants, boiler control, and central heating systems.

Direct-Acting Solenoid Valve

Direct-acting solenoid valves utilize a plunger that directly engages the orifice to control the flow of the substance. These valves are suitable for low-flow, low-pressure, and vacuum applications, such as laboratory dosing, analytical instruments, and compact automation systems.

Semi-Direct Operated Solenoid Valve

This design combines the features of direct-acting and indirect-acting valves, making it ideal for high flow rates and capable of operating from 0 bar (0 psi). Semi-direct operated valves are often chosen for applications requiring rapid open/close cycles and reliable performance at varying pressures.

High Pressure Solenoid Valve

High-pressure solenoid valves are perfect for flow control in environments with dangerous machinery or inaccessible lines, where other valves cannot be used. They are engineered for applications such as hydraulic testing, fuel injection, and high-pressure gas distribution, where safety and leak-tight operation are paramount.

Stainless Steel Solenoid Valve

With a stainless steel body, these valves are highly resistant to corrosion, abrasion, and extreme temperatures, making them suitable for chemical processing, pharmaceutical, food and beverage, and marine industries. Stainless steel solenoid valves ensure sanitary operation and long-term durability in harsh environments.

Miniature Solenoid Valve

Miniature or micro solenoid valves are ideal for sensitive medical equipment, including biotechnology devices, portable medical tools, dental equipment, and gas analyzers. Their small size, low power consumption, and fast response times make them perfect for precision dosing and analytical applications.

Butterfly Valve

Although not a solenoid valve by definition, actuated butterfly valves can be controlled with solenoid pilot valves. They regulate or isolate fluid flow using a rotating disc positioned in the center of a pipe, commonly found in HVAC, water treatment, and process automation systems.

Actuated Ball Valve

Contains a ball with a small hole and an actuator that rotates the ball to start or stop the flow, commonly used in high flow applications such as water distribution, chemical processing, and fuel lines. Solenoid pilot valves often control the pneumatic or electric actuators that operate these ball valves.

Tubular Solenoid Valve

These tube-shaped valves are generally used with DC power applications, offering a compact form factor for integration into tight spaces and portable devices.

Poppet Valve

Also known as mushroom valves, these control engine air/gas flow quantity and timing with a disc-shaped tapered plug. Poppet solenoid valves are widely used in internal combustion engine control, process automation, and pneumatic actuation.

Brass Solenoid Valve

Suitable for non-corrosive substances like inert gas, water, or light oil, but not for highly corrosive substances. Brass solenoid valves are commonly used in drinking water systems, irrigation equipment, and general-purpose industrial automation.

PTFE Solenoid Valve

Made from PTFE (Teflon®), these valves are excellent for handling harsh gases and corrosive fluids. PTFE solenoid valves are the preferred choice for chemical dosing, laboratory analysis, and semiconductor manufacturing where high purity and chemical resistance are required.

Still unsure which solenoid valve suits your needs? Compare the most popular solenoid valve types and their applications in our detailed buying guide.

Advantages of Solenoid Valves

Choosing solenoid valves for your fluid and gas control needs offers numerous advantages. With fewer moving parts compared to other types of valves, solenoid valves require less maintenance, resulting in reduced downtime and lower total cost of ownership. They can be operated remotely and integrated with programmable logic controllers (PLCs), building automation systems, or IoT devices, which is especially valuable in hazardous environments or hard-to-reach installations. Additionally, solenoid valves can be designed for portability and battery-powered operation, making them perfect for mobile and emergency systems.

Solenoid valves are also highly versatile, functioning with hydraulic, pneumatic, or electric power sources. Their rapid switching capability ensures precise timing in automated processes, critical for manufacturing, laboratory automation, and safety shutdown systems. Energy-efficient coil designs and low-leakage construction further enhance sustainability and environmental compliance.

Want to know how solenoid valves can improve efficiency in your facility? Read about real-world solenoid valve applications and customer success stories.

Accessories

Common accessories for solenoid valves include electrical connectors, manifolds, mounting brackets, screws, gaskets, indicator lights, position sensors, and cable assemblies. Among these, connectors are the most frequently used, as they facilitate the assembly of more complex valve systems and modular manifolds. Manifolds enable the integration of multiple solenoid valves into a compact, centralized assembly for controlling several fluid lines simultaneously. Indicator lights and position sensors provide real-time feedback for system status monitoring and troubleshooting.

Consult with your manufacturer or supplier to determine the best accessories and installation kits for your specific application. Many suppliers offer complete solenoid valve kits or plug-and-play solutions for rapid deployment in OEM and retrofit projects.

Looking for accessories to simplify your solenoid valve installation? Browse our accessory catalog or request a custom accessory kit.

Installation

Whether you choose to install your solenoid valves yourself, have your supplier handle it, or hire a professional industrial automation contractor, all options are perfectly acceptable. If you decide to take on the installation yourself, follow these guidelines and the manufacturer’s instructions to ensure a successful and reliable installation:

- Position solenoid valves at crucial points in your fluid or air system to ensure optimal performance and ease of maintenance.

- Ensure valves are installed in a dry, well-ventilated area to prevent overheating and adverse reactions. For outdoor or harsh environments, select valves with appropriate IP or NEMA ratings.

- Look for an arrow on the valve body indicating the flow direction and install it accordingly to prevent backflow or malfunctions.

- Use the correct electrical connections and voltage specified for your solenoid coil to ensure safe operation and prevent coil burnout.

- Test the system for leaks and proper operation before putting it into full service.

For complex installations involving hazardous fluids, high pressures, or explosion-proof valves, it is best to work with a qualified professional or consult your supplier’s technical support team.

Need help with solenoid valve installation? Access step-by-step installation guides or schedule on-site support with our certified technicians.

Proper Care for Solenoid Valves

With proper maintenance, your solenoid valves can have a long operational lifespan and deliver consistent, trouble-free performance. Regular cleaning on a set schedule is essential to prevent buildup of contaminants, scale, or debris, especially in water and chemical applications. Using the right tools, such as those in a maintenance kit, allows you to clean and service the valves without fully disassembling the valve assembly, minimizing downtime.

Besides routine cleaning, address any leaks, excessive noise, or sluggish operation immediately by inspecting and cleaning the valves. Periodically check electrical connections, seals, and moving components for signs of wear or damage. Replace worn seals and coils as needed to maintain optimal performance.

To enhance the performance and longevity of your valve system, it’s crucial to avoid using incompatible fluids or gases, as these can cause premature wear and damage to your valves. Always verify chemical compatibility before selecting a valve. Additionally, prevent freezing of substances inside the valve and maintain the contents at appropriate temperatures and pressures to avoid damage and ensure reliable operation.

How do you maximize solenoid valve lifespan? See our expert maintenance checklist and troubleshooting guide.

Standards

The standards and certifications required for your solenoid valves depend on their application, the industry, and the location of use. Regulatory compliance ensures both product safety and process reliability.

For instance, if your valves will contact drinking water, they must be lead-free. In the United States, drinking water and plumbing codes stipulate that RO (reverse osmosis) equipment must be NSF (the National Science Foundation) certified and comply with NSF 61-G, a regulation ensuring lead-free materials. For international applications, solenoid valves must be certified lead-free by NSF International and accredited by both ANSI (American National Standards Institute) and the Standards Council of Canada (SCC).

Additionally, the National Electrical Manufacturers Association (NEMA) provides standard designations for valve suitability. Generally, a higher NEMA type number indicates the valve can endure harsher conditions. For example, NEMA Type 1 valves are suitable for indoor use, while NEMA Types 7 and 9 are designed for environments with explosive dust, gases, or vapors. For European installations, look for CE marking, ATEX certification for explosive atmospheres, and WRAS approval for potable water systems.

Other relevant standards may include UL/CSA certification (for electrical safety), RoHS (Restriction of Hazardous Substances), REACH (chemical regulations), FDA compliance (for food and pharmaceutical applications), and ISO 9001 (quality management). Always confirm with your supplier which standards their solenoid valves meet for your application.

Need to meet a specific industry standard? Consult our compliance checklist or ask about certified solenoid valve options.

Things to Consider

When selecting solenoid valves for your application, ensure your chosen manufacturer or supplier can fulfill all your specifications, including technical requirements, certifications, lead times, after-sales support, and budget constraints. Key considerations include:

- Flow and pressure requirements: Ensure the valve can handle your maximum operating conditions.

- Chemical compatibility: Select valve and seal materials suitable for your process media.

- Voltage and power supply: Choose a coil compatible with your system voltage and power constraints.

- Certification and compliance: Confirm the valve meets all applicable local, national, and international standards.

- Lead time and availability: Opting for quick-shipment programs can sometimes be more advantageous than standard shipping options, so be sure to discuss this with potential suppliers.

- Support and service: Prioritize manufacturers that provide robust support systems, including installation assistance, onsite training, technical consultation, maintenance, and parts replacement services.

Most importantly, work with a manufacturer or distributor you can trust. To find a reliable and experienced supplier, check out our comprehensive list on this page and review customer testimonials, case studies, and application notes.

Need help choosing the best solenoid valve supplier? Compare top-rated manufacturers and request custom quotes today.

Check out our Solenoid Valves website

Check out our Linear Actuators website

What are the main advantages of using solenoid valves?

Solenoid valves offer fast and safe switching, exceptional reliability, long operational life, and compact design. They require less maintenance due to fewer moving parts, support remote operation and automation, and can be integrated with PLCs and IoT devices. Their versatility and rapid switching capability make them ideal for process automation and safety systems.

Which industries commonly use solenoid valves?

Solenoid valves are widely used in residential, appliance, industrial, and commercial sectors. Applications include refrigeration, HVAC, power washing, agricultural equipment, pneumatic and hydraulic systems, automotive fuel and emissions, water treatment, irrigation, fire suppression, and a range of household appliances.

What materials are solenoid valves made from?

Solenoid valves are constructed from plastics like PVC, polypropylene, PTFE, and CPVC, as well as metals such as stainless steel, bronze, aluminum, and brass. Seals are made from materials including Viton, NBR, EPDM, PTFE, and sometimes stainless steel to ensure compatibility with various fluids and operating conditions.

What are the different types of solenoid valves?

Solenoid valves come in a wide variety of types, including water, air (pneumatic), oil, chemical, steam, proportional, pilot-operated, direct-acting, semi-direct operated, high-pressure, stainless steel, miniature, brass, and PTFE solenoid valves. They can be categorized by the material controlled, construction/design, and power source (e.g., 12V, 24V, AC/DC).

What standards and certifications apply to solenoid valves?

Relevant standards include NSF (NSF 61-G) for drinking water, ANSI, SCC, CE marking, ATEX for explosive environments, WRAS for potable water, UL/CSA for electrical safety, RoHS, REACH, FDA compliance, and ISO 9001. NEMA ratings define environmental protection, and certification requirements depend on the application, industry, and location.

How should solenoid valves be installed and maintained?

Install solenoid valves according to manufacturer instructions, ensuring correct orientation, dry and well-ventilated placement, and proper electrical connections. Maintenance includes regular cleaning to prevent contamination, inspecting seals and electrical parts, addressing leaks or unusual noise, and using only compatible fluids. Professional help is recommended for hazardous or complex installations.

What factors should be considered when selecting a solenoid valve?

Key considerations include flow and pressure requirements, chemical compatibility, required certifications, required voltage and power, lead time, availability, support services, and the manufacturer’s reputation. Ensure all specifications are met to suit the intended application and operating environment.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services