These valves have an electromechanical mechanism to control them. The characteristics of the electric current used, the strength of the magnetic field produced, the mechanism used to control the fluid, and the fluid that is controlled vary between solenoid valves. The linear plunger-type, rocket, and pivoting armature actuators use distinct mechanisms. The valve uses a design with two ports for fluid regulation, or it can use a design with three or more ports to switch flows between ports. Valve placement on multiple manifold solenoids is contiguous. Read More…

Solenoid Solutions manufacturers custom direct-acting 2 and 3-way solenoid valves and multi-valve manifolds for OEMs in the medical, appliance, transportation, power generation and industrial equipment markets.

Our solenoid valves are all tested in house following very strict quality guidelines. We opened our doors in 1936 and ever since then we have been committed to bringing top of the line products and customer service that cannot be beat!

At Plast-O-Matic Valves, we are dedicated to designing and manufacturing high-performance fluid control solutions, with solenoid valves as a core part of our expertise. We take pride in engineering these valves with precision and reliability, ensuring they deliver consistent performance in demanding applications across a wide range of industries.

At Brandstrom Instruments, we are dedicated to delivering reliable and innovative solutions in fluid control, specializing in the design and manufacturing of high-quality solenoid valves. With decades of experience in engineering precision components, we take pride in offering products that meet the strict demands of industries requiring accurate flow regulation, durability, and efficiency.

We are proud to be DEMA® Engineering Company, a trusted name in fluid control and dispensing solutions. With decades of expertise, we design and manufacture high-quality solenoid valves that deliver reliable performance in a wide range of industrial and commercial applications.

At Aquatrol, we take pride in being a trusted manufacturer of high-quality solenoid valves designed for dependable performance across a wide range of industries. With decades of hands-on expertise, we have built a reputation for precision engineering, innovative solutions, and a commitment to excellence that ensures every product we deliver meets the highest standards.

More Electric Solenoid Valve Manufacturers

How Solenoid Valves Work

Solenoid valves are a critical component in fluid control systems, widely used across industrial, commercial, and residential applications. These electromechanically operated valves utilize an electric current to create a magnetic field, which actuates the valve mechanism. This enables precise, rapid, and automated control of liquid and gas flow in pipelines, machinery, and process equipment.

Solenoid valves come in an array of designs, primarily distinguished by the number of ports and fluid channels. The most common types include two-way and three-way solenoid valves. A valve is described as "normally open" (NO) when it remains open in its de-energized state (no current applied), allowing fluid flow. Conversely, a "normally closed" (NC) solenoid valve blocks flow until the solenoid is energized, opening the internal passage. These fundamental configurations support countless fluid automation needs, from simple on/off control to more complex distribution and mixing tasks.

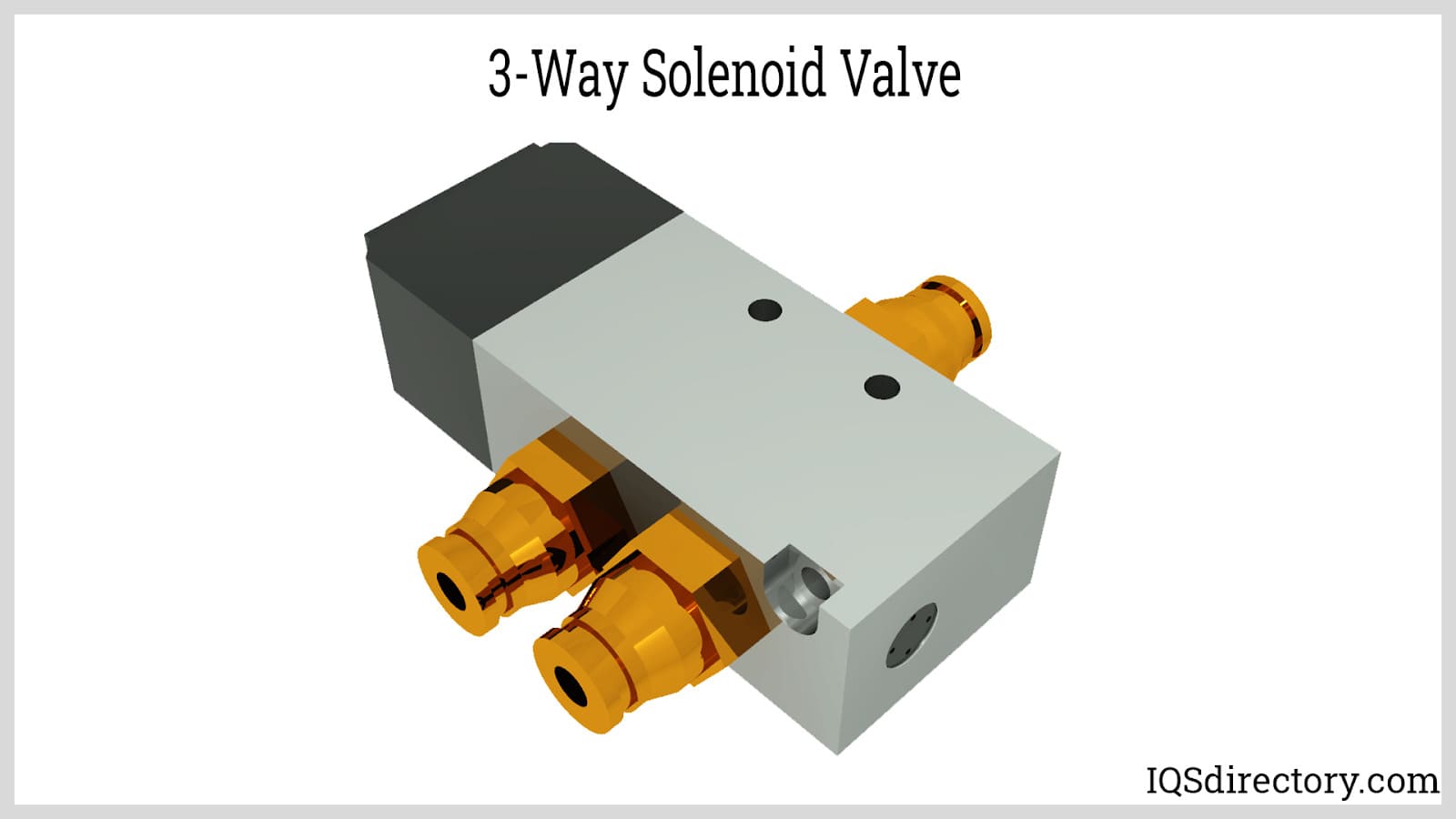

Advanced designs, such as three-way solenoid valves, offer enhanced versatility. These valves feature three ports and can direct flow between different channels, commonly used for diverting, mixing, or exhausting fluids. Depending on the application requirements, solenoid valves are selected based on their operating pressure range, response time, flow coefficient (Cv), and compatibility with the process media.

Direct-acting solenoids are ideal for low-pressure and low-flow applications, as the electromagnetic force directly actuates the valve mechanism. For high-pressure systems or larger flow rates, pilot-operated solenoid valves utilize the system pressure to assist in valve actuation, enabling control of larger volumes with lower electrical energy input.

Key Questions: Exploring Solenoid Valve Functionality

- What is the difference between direct-acting and pilot-operated solenoid valves?

- How does a normally closed solenoid valve operate compared to a normally open type?

- Which solenoid valve configuration is best for mixing or diverting fluids?

- Where are solenoid valves commonly used in industrial automation?

Materials Applied in Solenoid Valves' Construction

The selection of construction materials for solenoid valves is crucial for ensuring long-term reliability, safety, and compatibility with process media. Commonly used valve body materials include stainless steel, brass, aluminum, and engineered plastics such as PVC or polypropylene. Stainless steel solenoid valves are prized for their corrosion resistance and suitability in aggressive or sanitary environments, such as chemical processing, food & beverage, and pharmaceutical industries. Brass solenoid valves are widely used for water, air, and inert gases due to their durability and cost-effectiveness.

Sealing materials are equally important, as they directly contact the controlled fluids. Seal choices typically include EPDM, Viton (FKM), NBR (Buna-N), and PTFE (Teflon), each offering unique chemical and temperature resistances. Selecting the correct seal material ensures leak-free operation and extended service life, especially in demanding applications such as steam, fuel, or aggressive chemicals.

Internal components, like the core, plug nut, and springs, must balance magnetic properties with corrosion resistance. The core tube is designed to be non-magnetic, facilitating the passage of the solenoid's magnetic field, while the core and plug nut are typically fabricated from magnetic stainless steel or iron alloys. Stainless steel is preferred in many designs for its balance of strength, corrosion resistance, and magnetic response.

Decision Factors: Choosing the Right Solenoid Valve Materials

- Is the valve compatible with the chemical composition and temperature of your process fluid?

- Does the application require sanitary or corrosion-resistant construction?

- What are the pressure and temperature ratings needed for your application?

- How do seal materials affect durability and maintenance cycles?

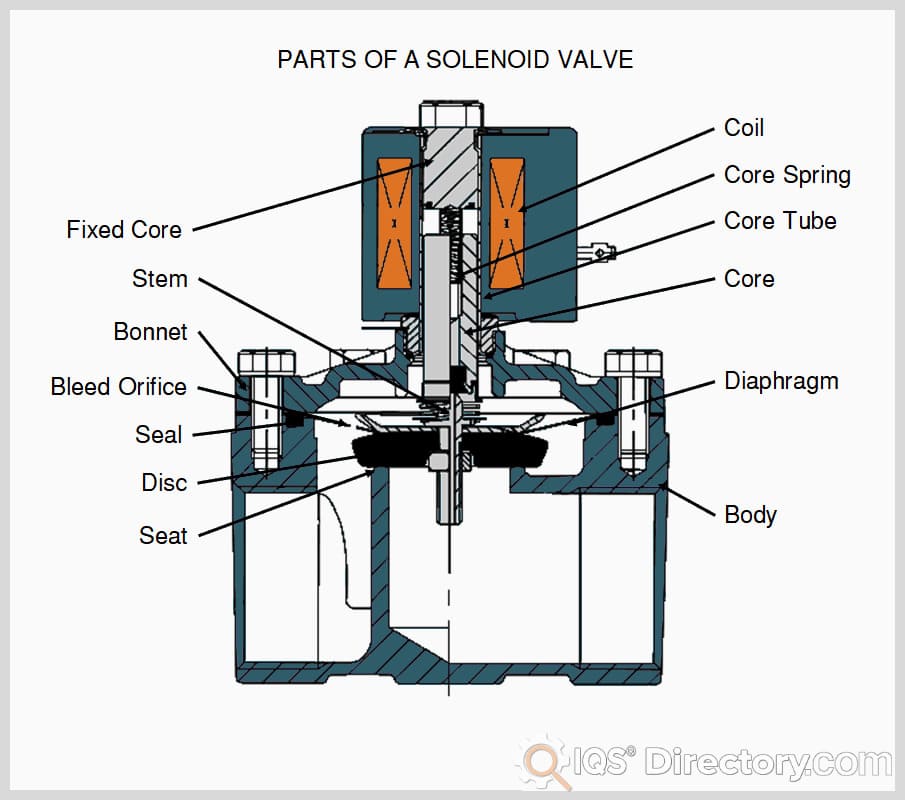

Solenoid Valve Components

Understanding the anatomy of a solenoid valve helps buyers and engineers select, maintain, and troubleshoot these devices. The main components of a solenoid valve include:

- Solenoid sub-assembly (core, core spring, shading coil, plug nut, core tube, solenoid coil, retaining clip)

- Core tube with a bonnet seal

- Diaphragm – body seal, hanger spring, diaphragm, bonnet

- Backup disk, washer, valve body

When electrical current energizes the solenoid coil, a magnetic field is generated, pulling the plunger (core) and actuating the valve mechanism. The core's movement opens or closes the valve, controlling fluid flow. Seals and diaphragms ensure leak-free operation even under fluctuating pressures. In de-energized states, springs return the core to its default position, maintaining the valve’s "normally open" or "normally closed" status.

The core tube is engineered to guide the core's motion while preventing magnetic shunting, which can reduce efficiency. In some designs, the core tube is a sealed metal shell, preventing fluid leakage and simplifying maintenance. However, this design may introduce greater magnetic resistance, requiring careful coil selection.

Maintenance & Troubleshooting: Solenoid Valve Components

- How do worn seals or diaphragms affect valve performance?

- What are common signs of solenoid coil failure?

- How often should solenoid valve components be inspected or replaced?

Solenoid Valve Types

Direct Acting Valves (DAVs)

Direct acting solenoid valves, or direct lift valves, utilize the magnetic force generated by the energized coil to directly open or close the valve seat. This design eliminates the need for auxiliary pressure, making direct-acting solenoid valves ideal for low-pressure, low-flow, and vacuum applications. These valves are commonly used in dosing, sampling, and rapid on/off control scenarios. However, because the solenoid must overcome the entire process pressure, these valves are generally limited to smaller orifices and lower pressures.

Pilot-Operated Solenoid Valves

Pilot-operated solenoid valves, also known as servo-assisted valves, use the solenoid coil to activate a small pilot orifice. This orifice then leverages the fluid's pressure to move a larger diaphragm or piston, enabling control of higher pressures and larger flow rates with minimal electrical input. These valves are extensively used in industrial automation, HVAC systems, water treatment, and high-flow process applications. While they offer energy efficiency and can handle higher capacities, pilot-operated valves require a minimum pressure differential to function properly.

Three-Way Solenoid Valves

Three-way solenoid valves feature three ports and are used to alternately apply pressure to and exhaust pressure from devices such as actuators, cylinders, or other fluidic components. These valves are essential in pneumatic and hydraulic automation for switching, mixing, or diverting fluids, and are commonly found in medical devices, laboratory automation, and household appliances like coffee machines and dishwashers. Three-way solenoid valves can be configured as normally closed, normally open, or universal, depending on the application needs.

Four-Way Solenoid Valves

Four-way solenoid valves, featuring four or more port connections, are integral to the operation of double-acting actuators and cylinders. These valves are used extensively in pneumatic and hydraulic directional control, enabling the precise movement of industrial machinery, robotics, and process automation systems. Four-way valves are available in universal, normally open, or normally closed configurations, offering versatility for complex control schemes. Learn more about four-way solenoid valves and their industrial applications.

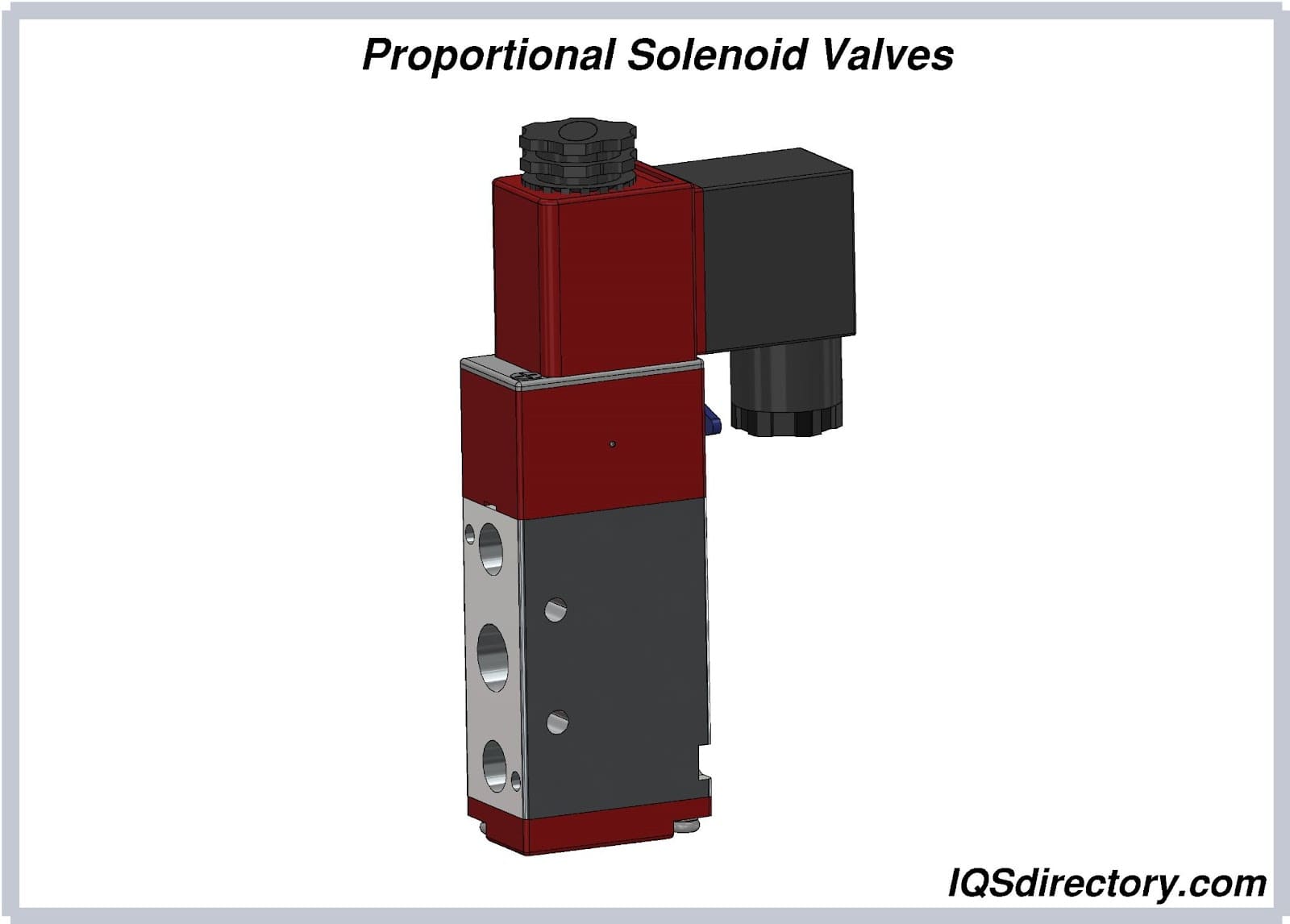

Specialty and Custom Solenoid Valves

In addition to standard valve types, specialty solenoid valves are engineered for unique requirements, such as explosion-proof solenoid valves for hazardous locations, proportional solenoid valves for variable flow control, and miniature solenoid valves for compact systems in medical or analytical devices. Custom solenoid valve assemblies can be designed to meet specific flow, pressure, and environmental specifications.

Choosing the Right Solenoid Valve Type

- Which solenoid valve is best for high-pressure fluid control?

- What type of valve is recommended for rapid switching or pulsing applications?

- Are specialty solenoid valves required for hazardous or sanitary environments?

- How do you size a solenoid valve for your flow and pressure needs?

Electric Solenoid Valves Applications

Electric solenoid valves play a vital role in a broad spectrum of industries, providing reliable and automated flow control for gases, liquids, and even steam. Their versatility, precision, and rapid actuation make them indispensable in modern automation, safety, and process optimization. Common applications include:

- Industrial Automation: Solenoid valves regulate air, water, oil, and chemicals in process control systems, manufacturing equipment, and pilot plant control loops.

- Water Treatment & Irrigation: Used in municipal water systems, irrigation controllers, and filtration plants for precise on/off and proportional flow control.

- HVAC Systems: Control refrigerants, steam, and chilled water in heating, ventilation, and air conditioning equipment.

- Home Appliances: Manage water inlet and distribution in washing machines, dishwashers, coffee makers, and ice machines.

- Medical Devices: Miniature solenoid valves enable accurate dosing, fluid mixing, and pneumatic control in laboratory and diagnostic equipment.

- Automotive & Transportation: Used for fuel control, emission management, and pneumatic actuation in vehicles and heavy machinery.

- Paintball and Recreational Equipment: Actuate gas and air for firing mechanisms and safety interlocks.

- Calibration & Test Stands: Enable automated cycling, leak testing, and calibration in quality assurance processes.

- Food & Beverage Production: Provide sanitary fluid control for mixing, filling, and cleaning operations.

Industry Use Cases: Where Are Solenoid Valves Used?

- How can solenoid valves improve efficiency in automated manufacturing?

- What role do solenoid valves play in water conservation and smart irrigation?

- Which solenoid valves are suitable for food-grade or pharmaceutical processes?

- Are miniature or low-power solenoid valves available for portable medical devices?

Benefits of Solenoid Valves

Solenoid valves offer a range of advantages that make them the preferred choice for automated fluid control:

- Reduced Power Consumption: Efficient coil designs minimize energy usage, particularly in pilot-operated or latching solenoid valves.

- Remote and Automated Operation: Electric actuation enables integration with sensors, timers, PLCs, and IoT systems for advanced process control.

- Rapid Response Time: Fast switching allows for precise timing and sequencing in automatic machinery.

- Versatility: Compatible with both AC and DC voltage supplies, and adaptable to a wide range of fluids and gases.

- Temperature Tolerance: Available in designs suitable for both high- and low-temperature environments, such as steam or cryogenics.

- Flexible Installation: Can be mounted in vertical or horizontal orientations without performance loss.

- Low Maintenance: Simple construction ensures minimal wear, with cost-effective repairs and replacements.

- Reliable Sealing: Advanced seal materials provide leak-free operation, even under challenging pressure and chemical conditions.

- Compact Size: Space-efficient designs are ideal for modular systems and retrofitting existing installations.

Buyer Considerations: Why Choose Solenoid Valves?

- What are the long-term cost savings of automated solenoid valve systems?

- How does switching speed impact process efficiency?

- What are the maintenance requirements for different solenoid valve designs?

- Are solenoid valves compatible with my control system (PLC, DCS, IoT)?

Choosing the Correct Electric Solenoid Valve Manufacturer

Selecting a reputable and experienced electric solenoid valve manufacturer is essential for ensuring product quality, technical support, and long-term reliability. The right manufacturer will offer a broad product range, customization options, and knowledgeable guidance tailored to your application requirements.

For the best results, compare at least 4 to 5 leading electric solenoid valve manufacturers using our comprehensive directory of solenoid valve companies. Each manufacturer profile highlights core competencies, certifications (such as ISO 9001, CE, or UL), material options, industry expertise, and customer testimonials. Use the integrated contact forms to request detailed quotations, technical datasheets, or application engineering support.

Our proprietary website preview tool enables you to efficiently evaluate each supplier’s product offerings, from standard brass and stainless steel solenoid valves to custom-engineered solutions for OEM projects. Once you’ve identified potential partners, use our streamlined RFQ (Request for Quote) form to submit your project specifications to multiple manufacturers simultaneously, ensuring competitive pricing and lead times.

Key factors to consider when choosing a solenoid valve supplier:

- Does the manufacturer offer the valve type, size, and material required for your application?

- Are technical support, documentation, and after-sales service readily available?

- Is the product certified for your industry (e.g., food-grade, explosion-proof, medical)?

- What is the manufacturer’s reputation for delivery times and product quality?

- Are custom solutions or large-volume discounts available?

Ready to Source Solenoid Valves?

Looking for a reliable electric solenoid valve supplier for your next project? Start your search by comparing manufacturers, browsing technical resources, and submitting your requirements for a personalized quote. Not sure which product fits your needs? Consult our expert guides or reach out to our technical team for advice on valve selection, installation, and maintenance best practices.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services