Handling high pressure, at pressures greater than 500 pounds per square inch, define this valve’s function. High-pressure solenoid valves are components of industrial equipment that can be operated electrically or pneumatically. The valves are often powered by actuators, typically fastened to the top of these valves. Read More…

Solenoid Solutions manufacturers custom direct-acting 2 and 3-way solenoid valves and multi-valve manifolds for OEMs in the medical, appliance, transportation, power generation and industrial equipment markets.

Our solenoid valves are all tested in house following very strict quality guidelines. We opened our doors in 1936 and ever since then we have been committed to bringing top of the line products and customer service that cannot be beat!

At Plast-O-Matic Valves, we are dedicated to designing and manufacturing high-performance fluid control solutions, with solenoid valves as a core part of our expertise. We take pride in engineering these valves with precision and reliability, ensuring they deliver consistent performance in demanding applications across a wide range of industries.

At Brandstrom Instruments, we are dedicated to delivering reliable and innovative solutions in fluid control, specializing in the design and manufacturing of high-quality solenoid valves. With decades of experience in engineering precision components, we take pride in offering products that meet the strict demands of industries requiring accurate flow regulation, durability, and efficiency.

We are proud to be DEMA® Engineering Company, a trusted name in fluid control and dispensing solutions. With decades of expertise, we design and manufacture high-quality solenoid valves that deliver reliable performance in a wide range of industrial and commercial applications.

At Aquatrol, we take pride in being a trusted manufacturer of high-quality solenoid valves designed for dependable performance across a wide range of industries. With decades of hands-on expertise, we have built a reputation for precision engineering, innovative solutions, and a commitment to excellence that ensures every product we deliver meets the highest standards.

More High Pressure Solenoid Valve Manufacturers

Examples of high-pressure solenoid valves include recirculation valves, dump valves, suction controllers, and back pressure valves. In the oil and gas sector, high-pressure valves are employed for various applications including high-pressure testing, isolation shutoff, and with high-pressure instrumentation panels. Maritime, mining, industrial, and automotive production industries also use high-pressure solenoid valves.

How a High-Pressure Solenoid Valve Works

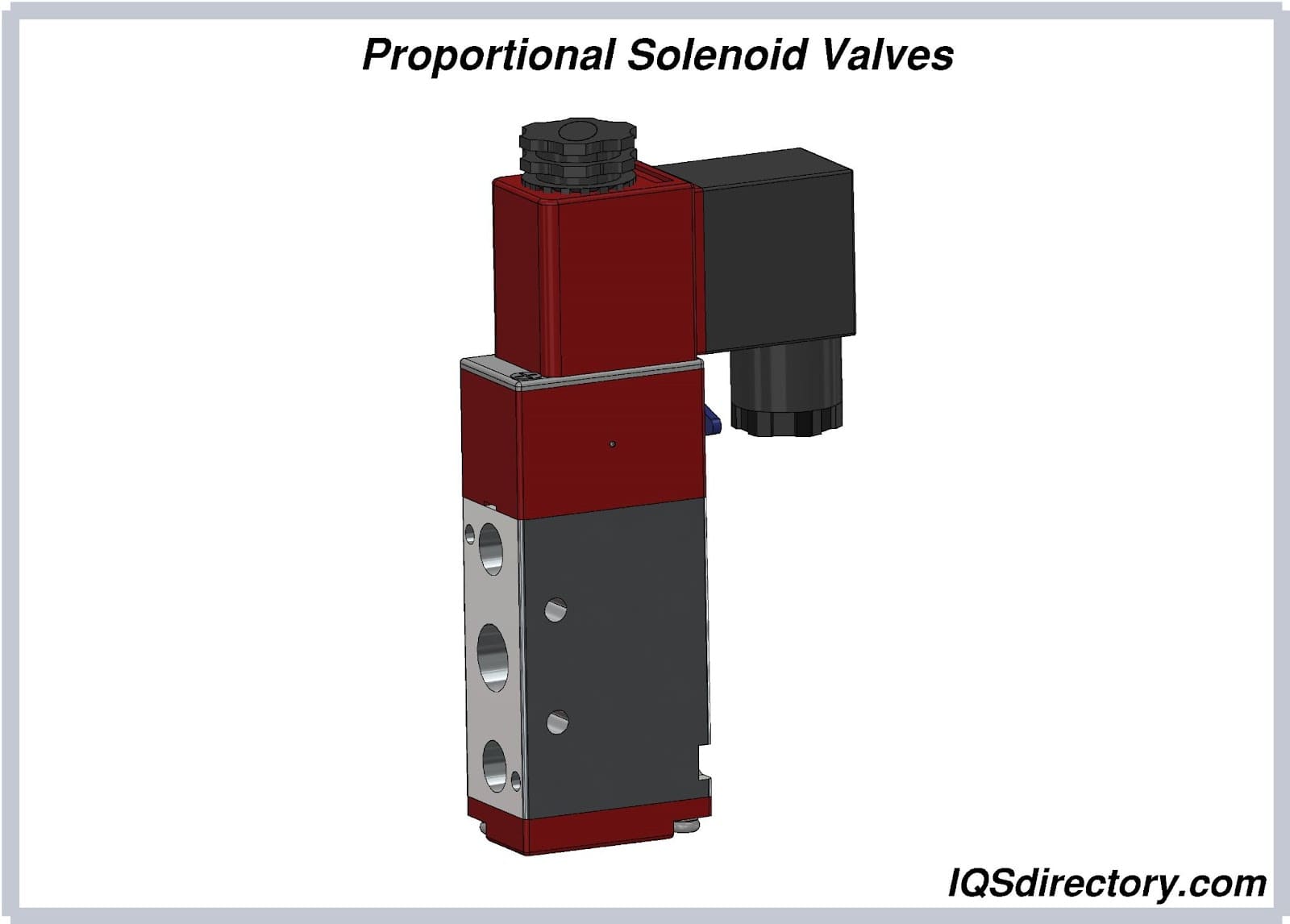

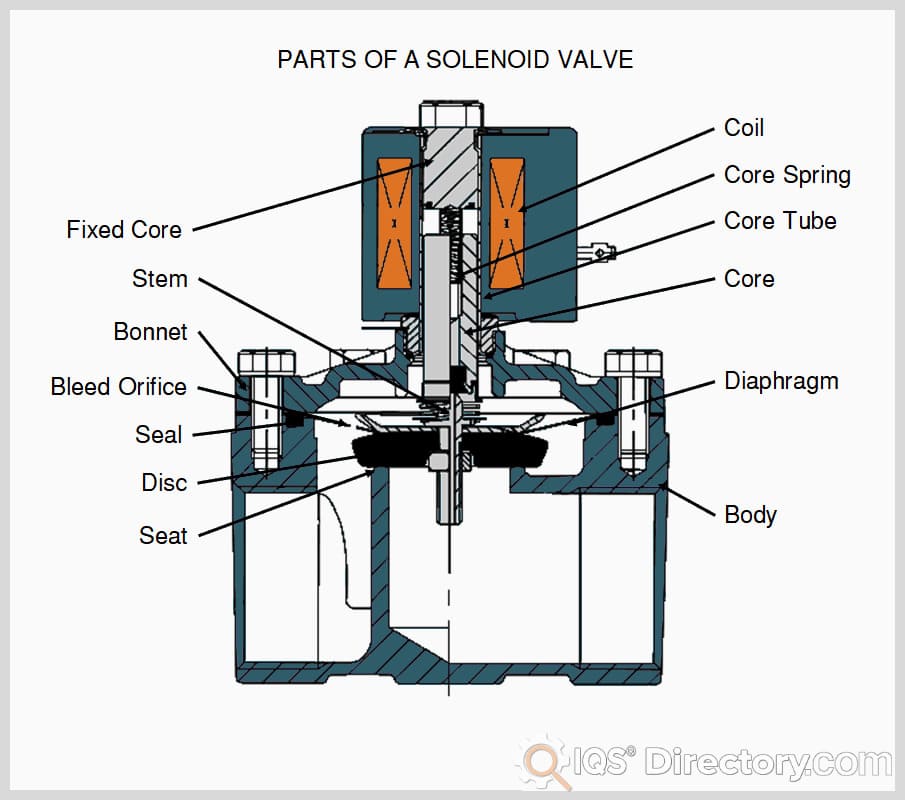

High-pressure solenoid valves work by lowering the pressure of a fluid or gas through a variable flow region inside the valve that permits a constant pressure drop across the valve. The spring-loaded, heat-resistant diaphragm of the high-pressure solenoid valve is normally attached to a mechanism that controls the valve's flow opening. The incoming fluid pressure interacts against the diaphragm's force to achieve force equilibrium.

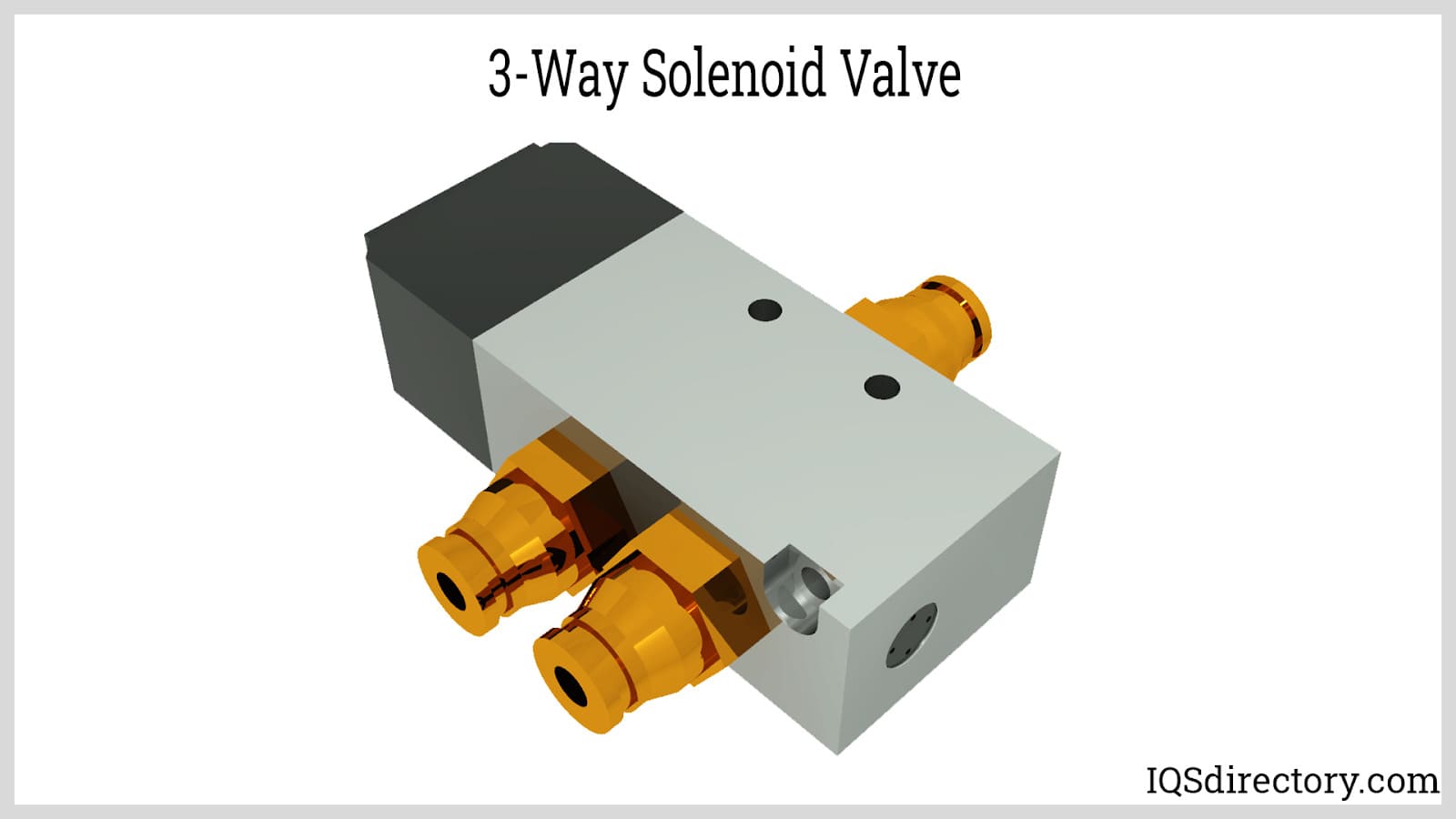

A normally closed (NC) or a normally open (NO) valve may be used in high-pressure solenoid valves. In an NC valve, a plunging pin or rod that stops the flow of air or fluid is held in place by a solenoid coil when it is not powered; the pressure of the air or fluid that enters the valve aids in keeping the valve closed as long as the pin is obstructing the passage. A normally open valve, meanwhile, has its plunger down to allow a fluid to flow when it is not powered.

Features of a High-Pressure Solenoid Valve

Depending on the design and material they are constructed from, most high-pressure solenoid valves may withstand operating temperatures up to 450°F. Manufacturers also provide optional valves for operating temperatures ranging from -423 °F to 1200 °F. Valve designs with non-rotating stems prevent stem-to-seat galling. Manufacturers may provide a Vee stem with an on/off function or a regulating stem to regulate the flow.

High-pressure valves include a metal-to-metal seat for a bubble-tight shutoff and extended stem and seat life. Different valve body designs are available from suppliers, and the two-way angle body pattern also has an optional replaceable seat.

Fitting a High-Pressure Solenoid Valve

Because high temperatures and pressures are typical in these applications, high-pressure components use a coned-and-threaded connection. High-pressure valves are offered in a range of tubing sizes and body styles to accommodate a wide range of applications. In addition, a line of fittings is provided to make it easier to convert to taper seal, medium-pressure, or other high-pressure threaded pipe systems.

Types of High-Pressure Solenoid Valves

Solenoid Pilot Valves With Cartridge Insert System

This is a novel alternative to traditional ball-seated type valves. These valves are essentially empty chambers that begin to function after a cartridge is inserted into them. These systems make replacement easier and lower the price of repairs.

Hydraulic Solenoid Pilot Valves Seated in Metal

Hydraulic solenoid pilot valves of this type include a design that has a balanced internal piloting system enabling the solenoid coil to switch the valve at high pressures, ensuring a leak-tight shutoff. Variations and specific uses of this type of valve include:

- 1000 bar solenoid valves

- 2/2 direct acting solenoid valves

- 500 bar good sealing solenoid valves for severe applications

- 500 bar solenoid valves for general use

- 200 bar solenoid valves that are compact and versatile

- 400 bar solenoid valves for high pressure

Ball-Seated Hydraulic Solenoid Pilot Valves

These valves provide a leak-tight shutoff, a balanced internal piloting system, a lever mechanism, and ceramic ball design. Low-powered operators can switch these valves at high pressures. The hydraulic interface control, valve's piston design, and ball-seated design guarantee positive control and leak-tight shutoff. These valves are available in various designs for various pressures and ambient temperatures, and can be installed in-line or on a subplate with multi-station manifolds.

Uses for High-Pressure Valves

Several sectors benefit from high-pressure valves and they are are necessary for the uses listed below:

- Water Jet Systems: Water jets employ high-pressure needle valves for cutting.

- Gas and Oil Industry Applications: Ball valves, high-pressure check valves, needle valves, and air-powered valves are used in refineries, wells, pipelines, and offshore oil rigs.

- Food Processing: Globe, pinch, disc, diaphragm, and control valves are essential in food processing activities requiring high pressure involving slurries, liquids, and powders.

- Chemical and Power Plants: High-pressure ball valves, needle valves, air-powered valves, and check valves are used in chemical plants and power plants.

Choosing the Correct High-Pressure Solenoid Valve Supplier

To make sure you have the most beneficial outcome when purchasing high-pressure solenoid valves from a gas solenoid valve supplier, it is important to compare at least 5 suppliers using our list of high-pressure solenoid valve companies. Each high-pressure solenoid valve supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each high-pressure solenoid valve business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple high-pressure solenoid valve companies with the same quote.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services