Solenoid control valves are essential in fluid control systems, offering precise regulation and automation capabilities. This article will delve into various aspects of solenoid control valves, including their general application, maintenance, selection criteria, and finding reputable suppliers. Users can optimize their solenoid control valves’ functionality, performance, and longevity. Read More…

Solenoid Solutions manufacturers custom direct-acting 2 and 3-way solenoid valves and multi-valve manifolds for OEMs in the medical, appliance, transportation, power generation and industrial equipment markets.

Our solenoid valves are all tested in house following very strict quality guidelines. We opened our doors in 1936 and ever since then we have been committed to bringing top of the line products and customer service that cannot be beat!

At Plast-O-Matic Valves, we are dedicated to designing and manufacturing high-performance fluid control solutions, with solenoid valves as a core part of our expertise. We take pride in engineering these valves with precision and reliability, ensuring they deliver consistent performance in demanding applications across a wide range of industries.

At Brandstrom Instruments, we are dedicated to delivering reliable and innovative solutions in fluid control, specializing in the design and manufacturing of high-quality solenoid valves. With decades of experience in engineering precision components, we take pride in offering products that meet the strict demands of industries requiring accurate flow regulation, durability, and efficiency.

We are proud to be DEMA® Engineering Company, a trusted name in fluid control and dispensing solutions. With decades of expertise, we design and manufacture high-quality solenoid valves that deliver reliable performance in a wide range of industrial and commercial applications.

At Aquatrol, we take pride in being a trusted manufacturer of high-quality solenoid valves designed for dependable performance across a wide range of industries. With decades of hands-on expertise, we have built a reputation for precision engineering, innovative solutions, and a commitment to excellence that ensures every product we deliver meets the highest standards.

More Solenoid Control Valve Manufacturers

Applications of Solenoid Control Valves

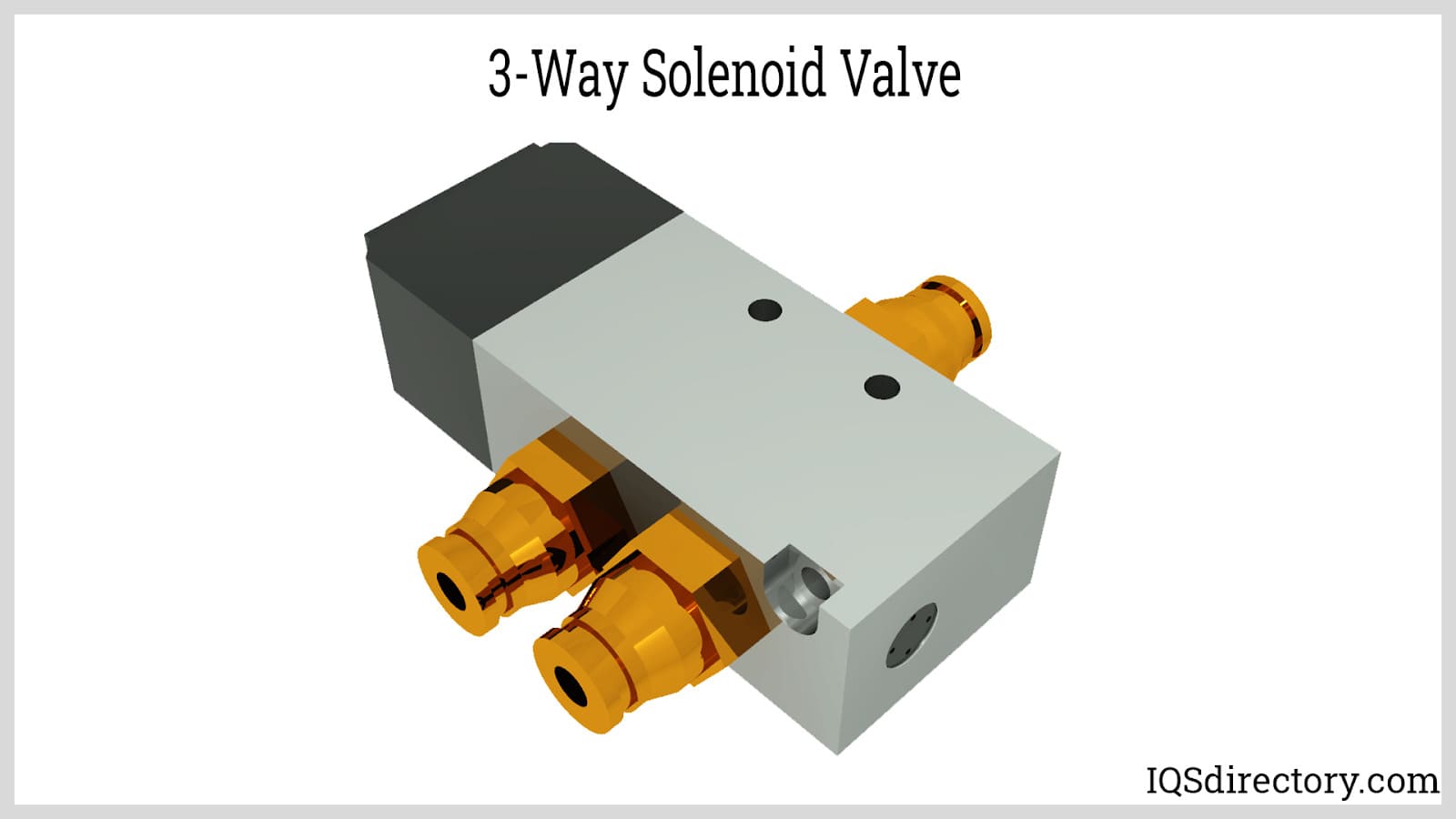

Solenoid control valves are electromechanical devices that control fluid flow by opening or closing the valve passage in response to an electrical signal. Their applications span across industries such as manufacturing, oil and gas, water treatment, automotive, healthcare, and more. These valves regulate fluid flow rates, enable automation, and ensure precise control of various processes and systems.

Maintenance of Solenoid Control Valves

Regular maintenance practices are essential for optimizing the performance and extending the lifespan of solenoid control valves. This includes inspecting for leaks, cleaning or replacing filters to maintain proper fluid flow, checking electrical connections for security and corrosion, and lubricating moving parts to reduce friction. Protecting solenoid coils from environmental factors and electrical surges can be achieved by using protective covers or housings and installing surge protection devices. Troubleshooting common issues, such as valves failing to operate or erratic behavior, involves checking the electrical supply, inspecting the coils, and ensuring the valves are free from obstructions. By following these maintenance practices, solenoid control valves can deliver reliable and efficient fluid control while minimizing the risk of malfunctions or downtime, ensuring optimal functionality over an extended period.

Replacing Solenoid Control Valves

Over time, however, solenoid control valves may exhibit signs of wear and tear, indicating the need for replacement to maintain optimal performance and reliability. One common sign is frequent leaks around the valve body or connections, indicating worn seals or damaged components. Inconsistent or erratic flow regulation, such as the valve not opening or closing as intended or experiencing fluctuations in fluid control, indicates potential valve deterioration. Coil failure, characterized by the valve not responding to electrical signals or inconsistent operation, may also necessitate replacement. Additionally, if the valve sticks in either the open or closed position, it may no longer provide the desired flow control. Recognizing these warning signs is crucial to avoid potential system failures, inefficiencies, or safety risks. Monitoring the performance of solenoid control valves and promptly replacing them when these signs arise ensures effective operation for the long term.

Selecting a Solenoid Control Valve

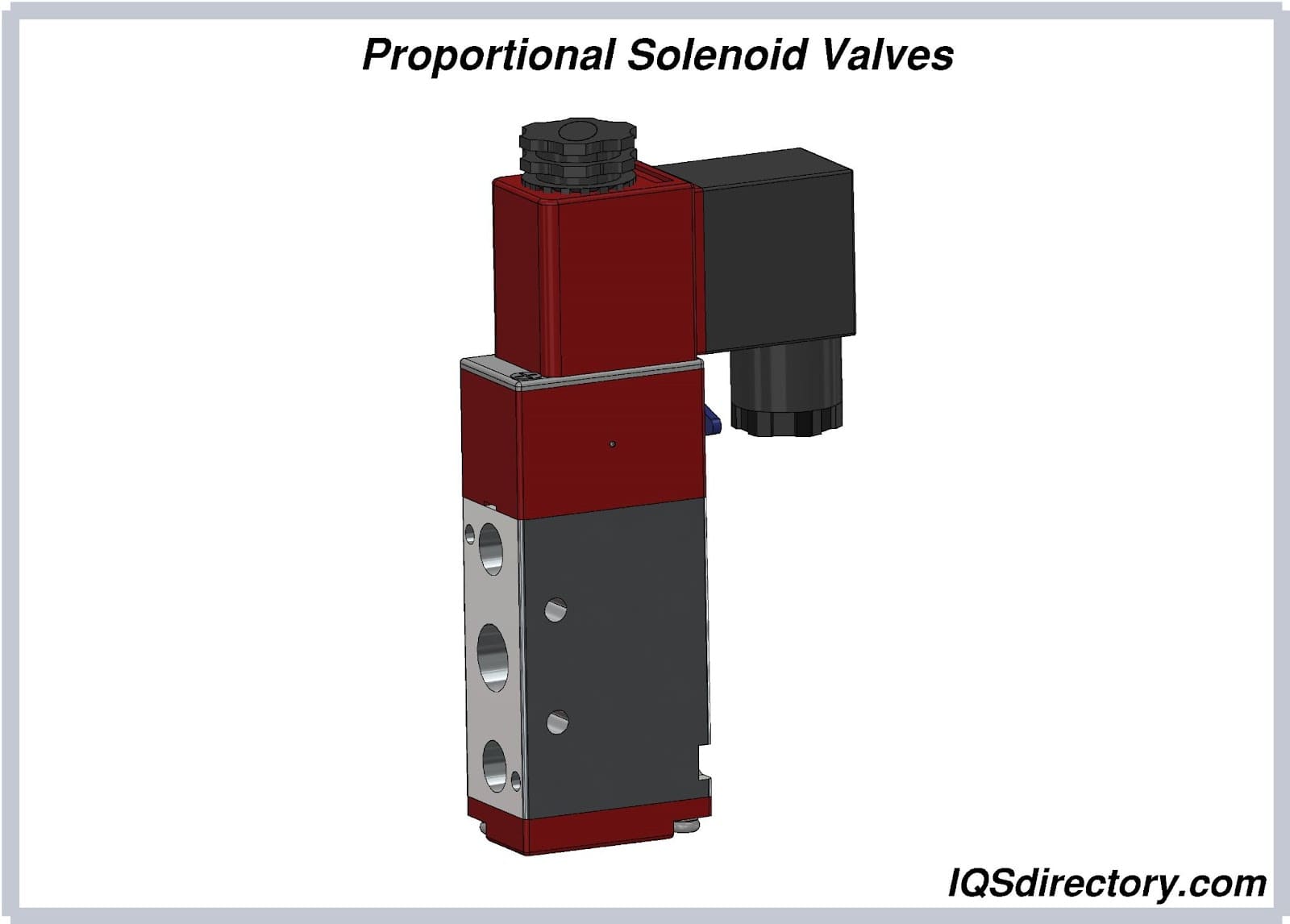

Selecting the right solenoid control valve for a specific application is vital.. Several factors should be considered during the selection process. First, evaluate the compatibility of the valve with the fluid being controlled, taking into account factors such as chemical compatibility, viscosity, and temperature. Additionally, consider the pressure and temperature ratings of the valve to ensure it can handle the system's operating conditions. Assess the flow requirements, including flow rate and direction to choose a valve that provides necessary control. Valve size should align with the pipe diameter and the system’s flow capacity.

To make an informed decision, consult the manufacturer's specifications and technical data sheets, which provide detailed information on the valve's capabilities. Additionally, seek advice from industry experts or valve suppliers who can provide expertise and experience. By considering these factors and consulting with experts, one can select an appropriate solenoid control valve that meets the system's fluid compatibility, pressure, temperature, flow, and size requirements, ensuring optimal performance and reliable fluid control.

Consequences of Choosing the Wrong Valve

Choosing the wrong solenoid control valve for a specific application can have several undesirable consequences. One major consequence is compromised fluid control. If the valve is not properly sized or suited for the required flow rate, pressure, or temperature of the system, it may result in inadequate or excessive fluid flow. This can lead to inefficiencies, poor performance, or even damage to the equipment or process being controlled. Additionally, using a valve that is not chemically compatible with the fluid being controlled can cause corrosion, contamination, or leaks, jeopardizing the system's integrity and potentially leading to safety hazards. Inadequate sealing or valve response can, additionally, result in fluid leakage, loss of control, or even system failures. Furthermore, selecting a valve that cannot withstand the operating conditions, such as high pressure or temperature, may result in premature wear and frequent maintenance. Carefully consider the application requirements and select a solenoid control valve designed to handle fluid, operating conditions, and performance demands.

Choosing the Right Solenoid Control Valve Company

To ensure the best result when purchasing solenoid control valves, compare several companies using our directory of solenoid control valve companies. Each solenoid control valve company has a business profile page highlighting areas of experience and capabilities. Each profile has a contact form to directly communicate with the company for more information or to request a quote. Review each company’s website using our patented website previewer to quickly learn each company’s specialty. Then, use our simple RFQ form to contact multiple solenoid control valve companies with the same form.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services