A solenoid water valve is utilized to enable or restrict water flow through a pipe system. Solenoid water valves are typically single-piece devices made of a solenoid coil and a piston or tappet valve. The solenoid plunger and the valve stem are connected so that when the solenoid is turned on, the valve mechanism opens, and water can flow through. Read More…

Solenoid Solutions manufacturers custom direct-acting 2 and 3-way solenoid valves and multi-valve manifolds for OEMs in the medical, appliance, transportation, power generation and industrial equipment markets.

Our solenoid valves are all tested in house following very strict quality guidelines. We opened our doors in 1936 and ever since then we have been committed to bringing top of the line products and customer service that cannot be beat!

At Plast-O-Matic Valves, we are dedicated to designing and manufacturing high-performance fluid control solutions, with solenoid valves as a core part of our expertise. We take pride in engineering these valves with precision and reliability, ensuring they deliver consistent performance in demanding applications across a wide range of industries.

At Brandstrom Instruments, we are dedicated to delivering reliable and innovative solutions in fluid control, specializing in the design and manufacturing of high-quality solenoid valves. With decades of experience in engineering precision components, we take pride in offering products that meet the strict demands of industries requiring accurate flow regulation, durability, and efficiency.

We are proud to be DEMA® Engineering Company, a trusted name in fluid control and dispensing solutions. With decades of expertise, we design and manufacture high-quality solenoid valves that deliver reliable performance in a wide range of industrial and commercial applications.

At Aquatrol, we take pride in being a trusted manufacturer of high-quality solenoid valves designed for dependable performance across a wide range of industries. With decades of hands-on expertise, we have built a reputation for precision engineering, innovative solutions, and a commitment to excellence that ensures every product we deliver meets the highest standards.

More Solenoid Water Valve Manufacturers

A valve return spring pulls the piston back down into its seat when the power to the solenoid is turned off, stopping the flow of water and resetting the solenoid. Smaller water supply systems, such as those found in washing machines, home and agricultural irrigation, and light industrial installations, typically use solenoid valves.

The accumulated stress in the spring cleverly forces the valve piston back to its seat, stopping the flow of water and resetting the solenoid in preparation for the subsequent cycle, when the power to the water solenoid valve coil is interrupted, and the plunger is released. Compared to other actuators, solenoids typically produce outputs of comparatively low power.

As a result, the water solenoid valve is typically employed in relatively light-duty applications. There are examples of solenoid water valves in dishwashers and washing machines, remote irrigation systems, and light engineering or industrial facilities. On the other hand, high-output actuators, such as geared electric motors and rotary hydraulic kinds, are frequently employed in heavier-powered valve applications.

How Solenoid Water Valves Work

The only true distinction between solenoid water valves and standard valves is that a solenoid triggers the valve mechanism rather than an operator input. Due to solenoids' linear actuation motion output, the valves are often vertical rise piston or poppet types. Depending on the necessary operational details, the water solenoid valve may be built of corrosion-resistant metals like brass or stainless steel, or different types of plastic. In addition, the solenoid coils may be rated for low-voltage direct current (DC) supplies or mains-voltage alternating current (AC) power sources.

Types of Solenoid Water Valves

Direct-Acting Valves

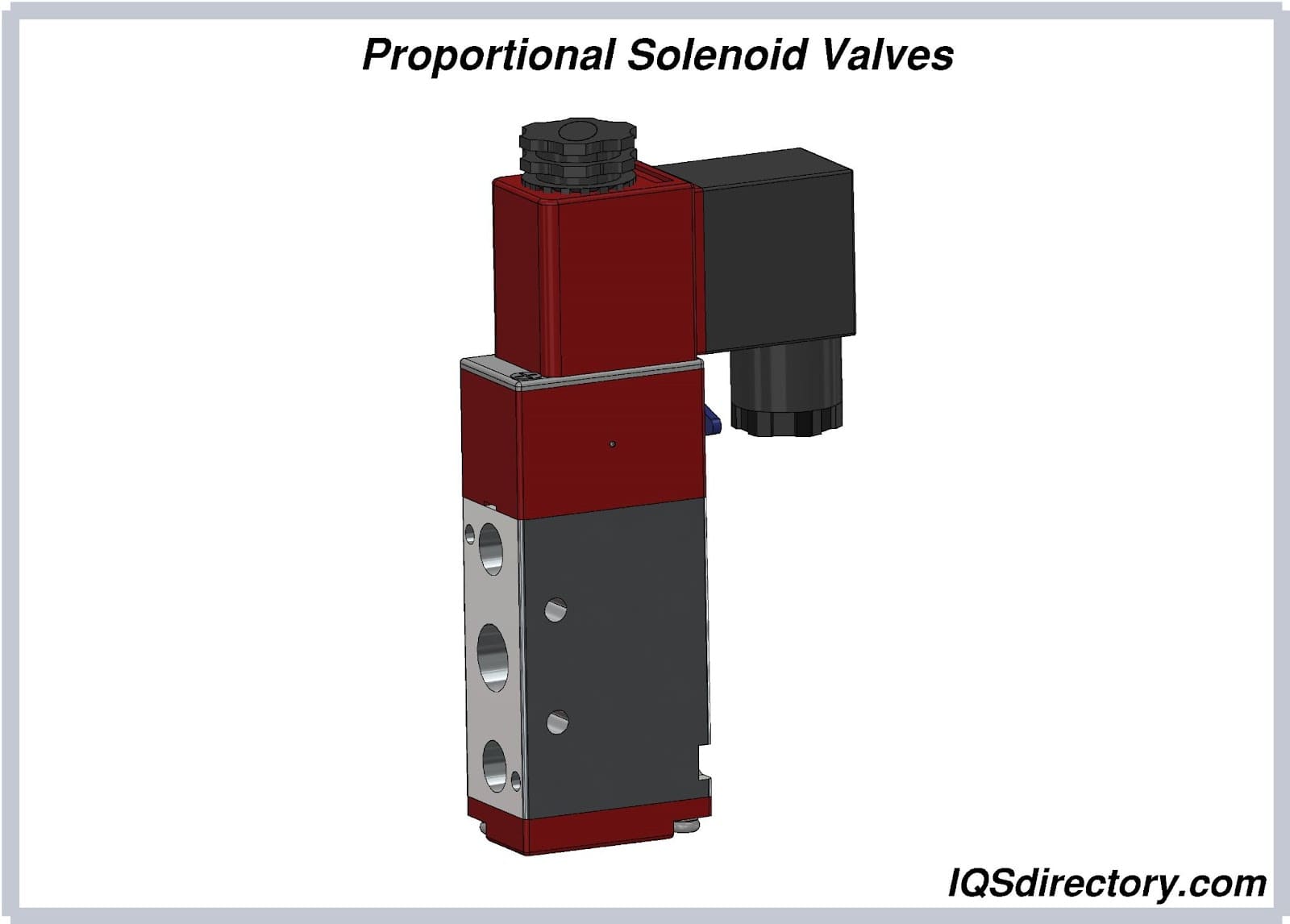

The phrase "direct acting" is typically used to describe solenoid water valves (or diaphragm solenoid valves). It implies that the solenoid valve's position can be directly influenced by energizing the solenoid coil. For instance, activating the solenoid coil in a direct-acting solenoid valve will move the diaphragm into its open position if the valve is closed in its resting position.

This classification does not necessarily imply a link between the valve's core tube and diaphragm, but rather that there is a direct control due to the electrical state, which is crucial to highlight. Furthermore, a direct-acting solenoid's ability to work fully without any pressure differential is one of its primary functions. This functionality indicates that there is no line pressure requirement for the valve to function effectively.

Indirect-Acting Valves

Pilot-operated solenoid valves, another name for indirect-acting solenoid valves, are typically always of the diaphragm style. The phrase "pilot operated" refers to the media functioning as a pilot to aid the valve's operation. This solenoid valve's inlet port typically has a tiny hole through which some media can pass to reach a cavity above the diaphragm. The media then exerts pressure on the top of the diaphragm in a usually closed valve, maintaining it in the closed position.

The media is pushed out of the top cavity and back into the main pressure line when the solenoid coil is activated, which causes the diaphragm to open. The main advantage of employing a solenoid valve with indirect action is that it uses less energy than a direct-acting valve. Therefore, indirect-acting solenoid valves are frequently more economical.

Normally Closed/Normally Open Solenoid Valves

These phrases describe the valve's idle condition, which is devoid of power. Despite being self-explanatory, they can also be referred to by other names. For example, it is possible to think of a normally closed solenoid valve as "energizing to close" and a normally open solenoid valve as "energizing to open." Normally closed or normally open most frequently refers to solenoids of the diaphragm or poppet variety that use a spring to reset the valve to its resting position after the coil has lost power.

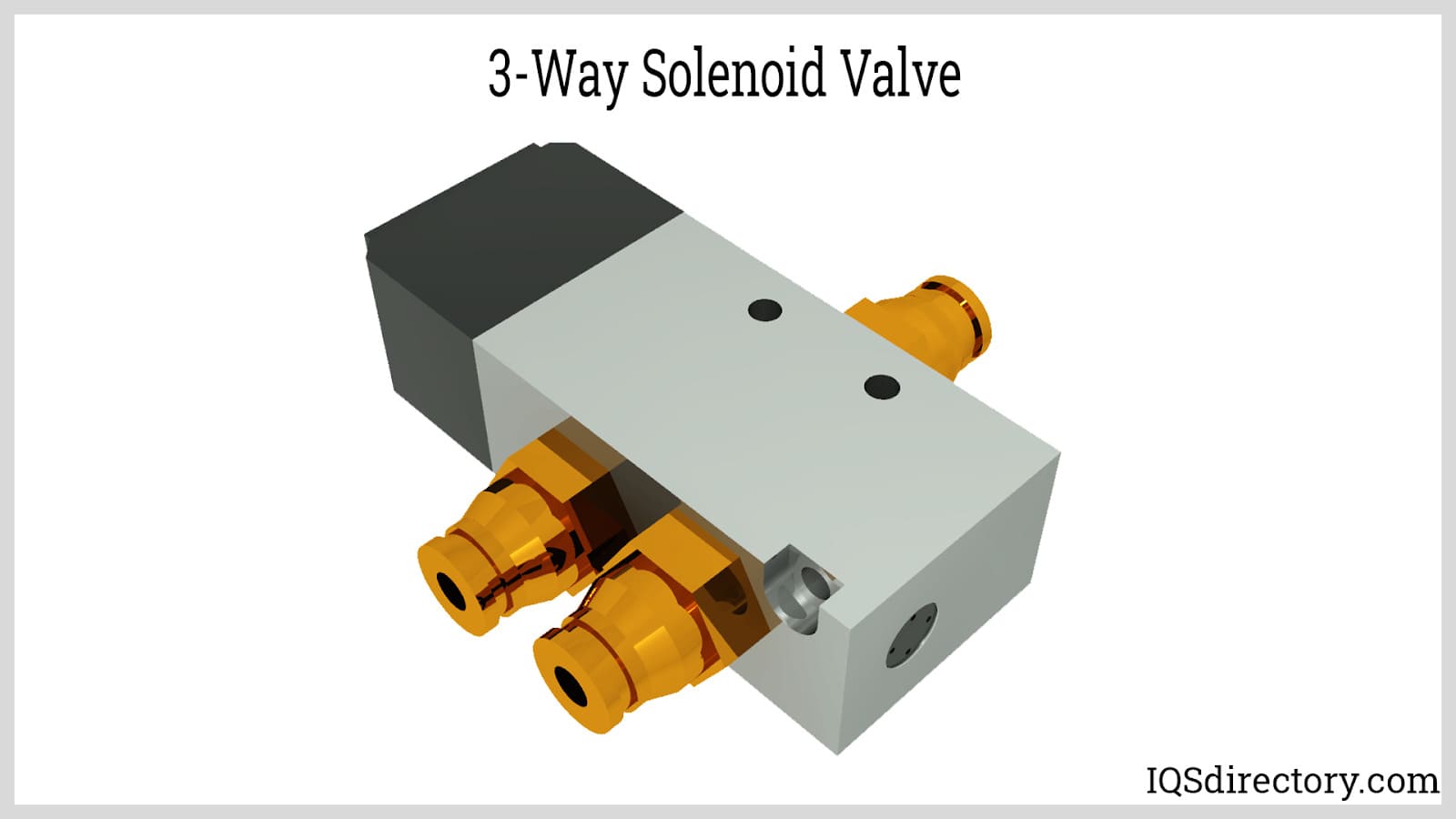

3/2-Way Solenoid Valves

The phrase "3/2-way" most frequently refers to a spool-type solenoid valve. However, a poppet-type valve may also be used in this form. The phrase "3 ports, 2 positions" can be extruded to represent this. Other valve types can use a similar acronym and the same formula. The most fundamental 3/2-way valves use port 1, which is blocked in its resting state, as the valve inlet, port 2, which is used as the valve outlet; and port 3, which is used as the exhaust.

The spool position changes and port one becomes blocked when power is given via the solenoid. Port 2 then flows to port 3 and exhausts the system. When the power is turned off, the spool returns to its resting position, and regular valve operation resumes. Because of this process, this kind of 3/2-way valve also goes by the name of spool or sol/spring valve. The most typical application for 3/2-way spool valves is as a pilot to a single-acting pneumatic actuator or pneumatic cylinder.

Choosing the Right Solenoid Water Valve Company

To make sure you have the most positive outcome when purchasing solenoid water valves from a solenoid water valve company, it is important to compare at least 4 to 5 manufacturers using our list of solenoid water valve manufacturers. Each solenoid water valve company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each solenoid water valve company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple solenoid water valve companies with the same form.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services